Metal Oxide (“METOX”)

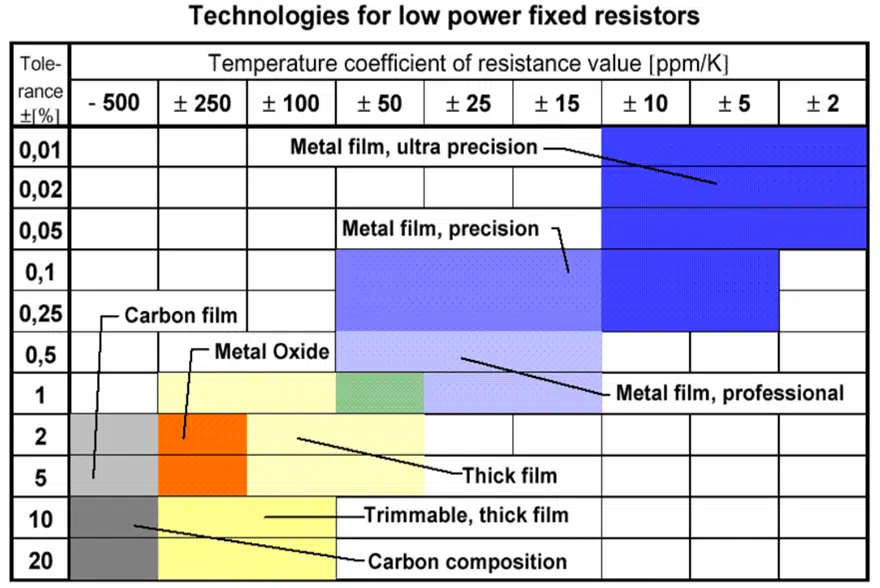

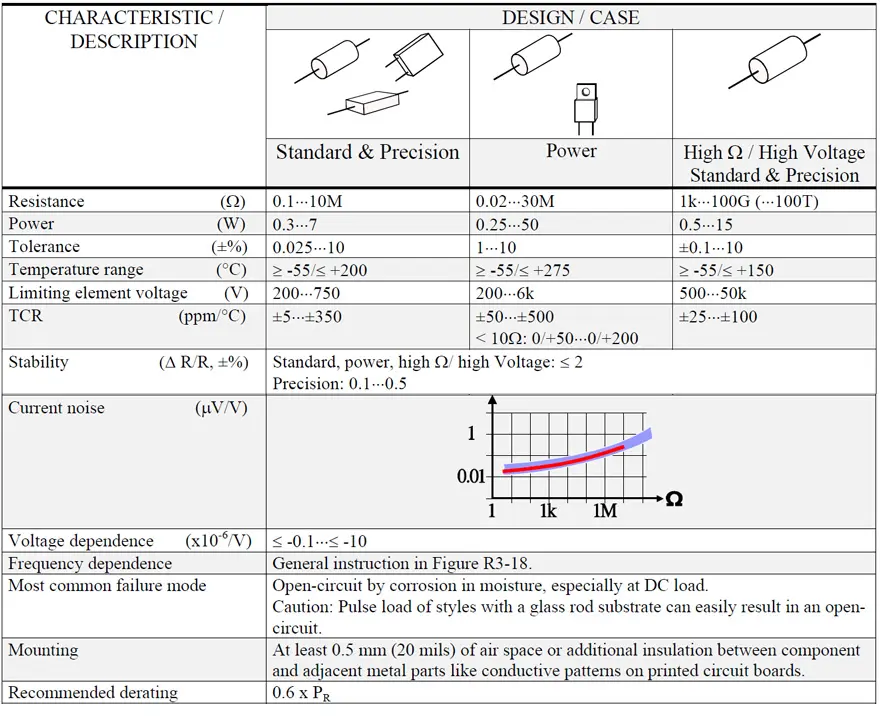

The metal oxide resistors have increasingly been replaced by metal film resistors. But, they still have a market, above all in the high ohmic-high voltage range. Precision designs exist in all resistance ranges.

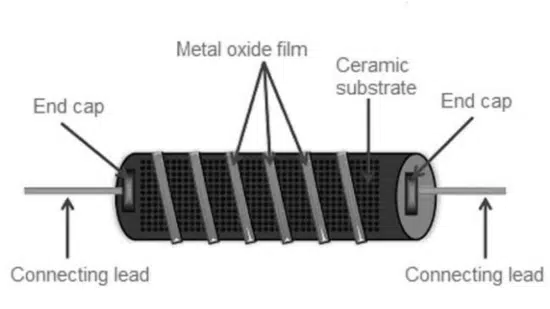

There are different ways of producing resistive metal oxide films. If we heat ceramic rods in a vapor of stannic chloride we get a coating of stannic oxide with good resistive characteristics. The thickness is approximately 1μm (0.04 mils). If we instead use glass that in a hot state is extruded in a stannic chloride vapor, it will result in a film of stannic oxide that is integrated with the glass to form an environment resistive resistance film. It will withstand several hundred per cent overload with good stability. On the other hand these resistors are extremely sensitive to stronger power pulses, also of short duration. Another way to produce metal oxide films is to first apply a metal film on the rods and then oxidize the film in an oxygen gas.

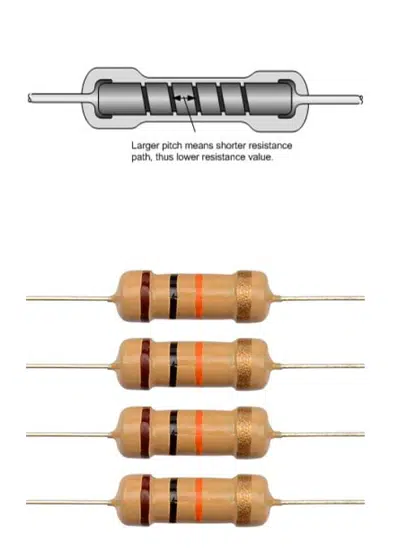

Normally the rods are spiraled in a conventional way. The lead pattern, however, can be formed in an inductance-limiting serpentine pattern as shown in Figure 8. and 9.

The metal oxide film has excellent noise characteristics, next to metal films the best. Unlike other films it does not run the risk of being oxidized at higher temperatures.

It already is oxidized. Thus, in certain power resistors Hot Spot temperatures up to 275 °C are permitted. But the user needs to check with the manufacturer’s data sheet about how much the chosen type can stand. It varies. Sometimes the power types are supplied with cooling plates integrated with the housing.

Certain types of metal oxide films also are suited for high voltage or high ohmic types, the latter in values up to at least 100 GΩ.

Carbon Film and Carbon Composition Resistors

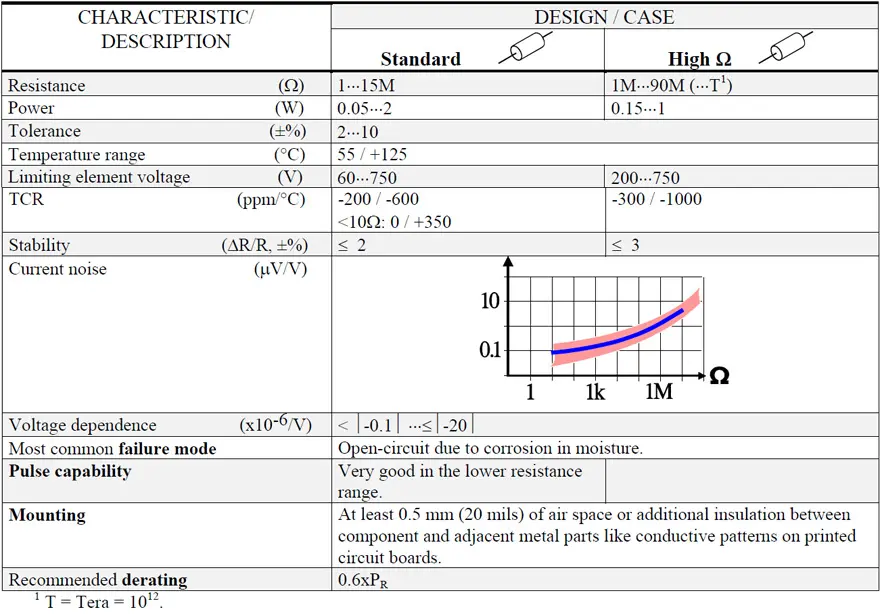

Carbon Film Resistors

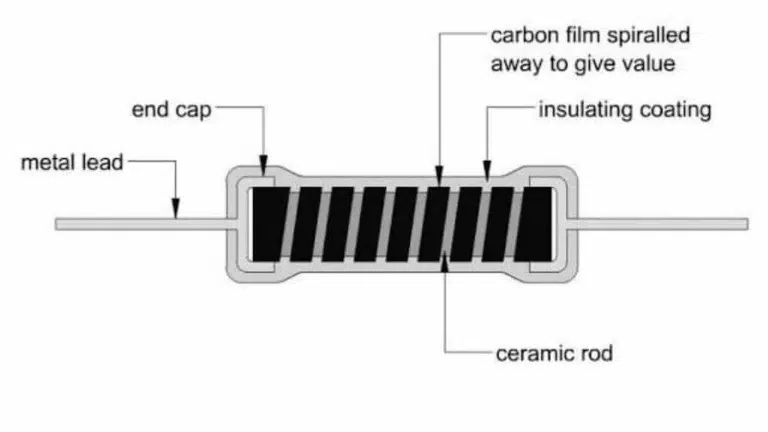

Carbon film resistors sometimes are called surface layer resistors. Better qualities are classified as “stable” with a ΔR/R that will stop at ≤1%. Their role has, to a great extent, been taken over by the metal film but they still have a market, especially as cheap 5 per cent E 24 components. At new designs one should yet consider replacing them with metal film resistors that also are offered in E 24, 5 per cent. See Figures 10. and 11.

If we apply crystalline carbon on ceramic rods in a vacuum chamber or if we heat them up to temperatures close to 1000 °C and then let them be hit by hydrocarbons, carbon will be deposited at a cracking process which will produce a stable, resistive carbon film with TCR values between –250 and –1000 ppm/°C depending on the resistance value. The thickness typically varies between 0.04 and 40 μm (1.6 and 1600 microinches). Low resistance values and corresponding thick films give an excellent pulse capability that may be further amplified if the film is non-spiraled.

Somewhere below 10Ω the manufacturers pass from carbon film to metal films (nickel, chromium-nickel or nickel-phosphorous) that is applied in a chemical bath or burning process or in an electrolytic bath. Thus, the user should carefully note in the catalogue sheets at which resistance value the TCR alters from, for example, –250 to maybe ±200 ppm/ °C.

The stability of carbon film resistors is good. The noise is comparatively high and increases with the resistance; low values may be relatively noise free, equivalent to that of the metal oxide.

High ohmic types exist in their most exclusive form in a hermetically sealed state, usually glass tubes, and may reach TΩ values (x 1012). Don’t touch such components with your fingers. Perspiring hands might be enough for shunting down the rated resistance markedly.

Carbon Composition Resistors

This component type is on the point of disappearing from the market. The manufacture of certain designs has ceased. In the most cases carbon composition resistors can be replaced by other both cheaper and qualitatively better components. Nevertheless, since they are part of many older designs we therefore will discuss them.

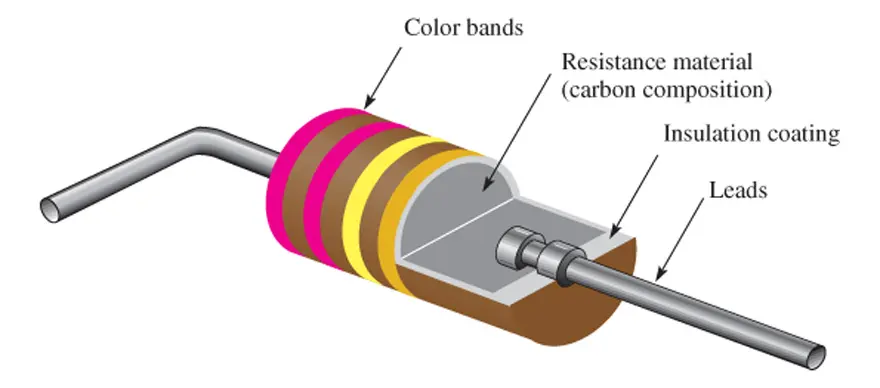

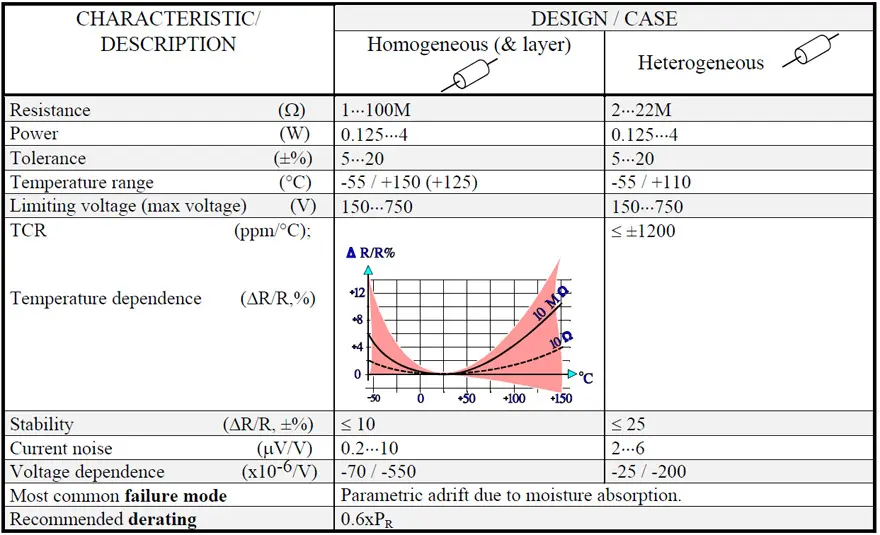

Carbon composition resistors exist in several designs: homogeneous and heterogeneous. In the first case a compound consisting of carbon powder and binder together with a resin is molded to a resistive body. In the latter case the carbon powder is mixed with a filling, usually silica or aluminum oxide, before it is molded. This type has the poorest stability and parameter characteristics. In a third variant a dispersion of graphite and binder is applied on a glass tube and then dried. The parameter characteristics of that layer type are comparable with those of the homogeneous composition type but the construction is very vulnerable.

The homogeneous, molded type is qualitatively the best but also the most expensive. It is usually used in such applications where an open circuit failure mode would result in a serious safety risk. In Figure 9. a cutaway view is shown of homogeneous composition resistor.

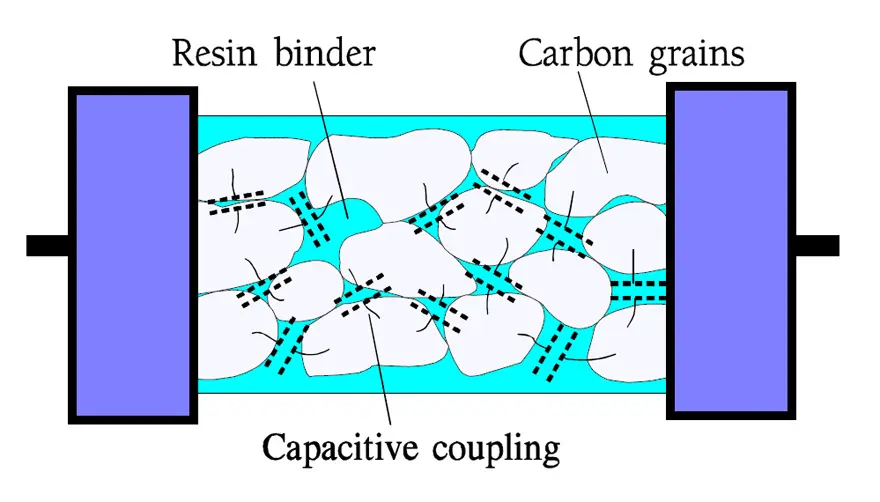

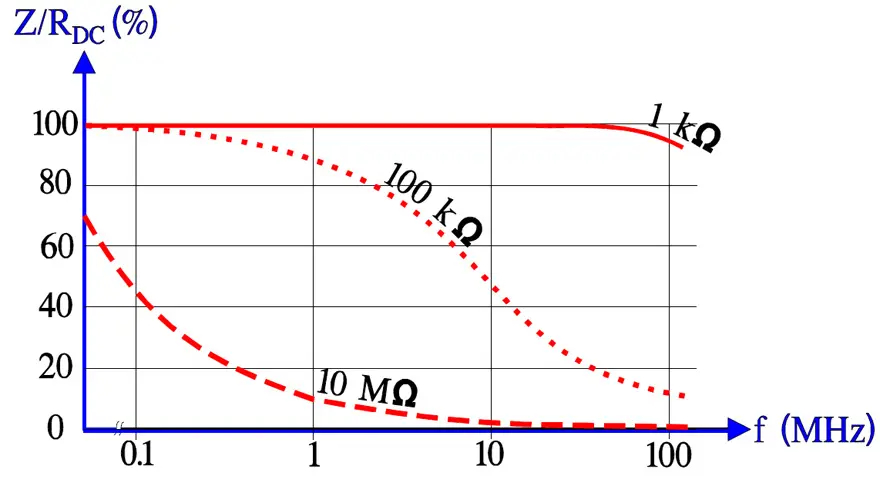

Just as in metal glaze resistors the conduction mechanism consists of conductive granules embedded in an isolator compound (Figure 10.). There is shown the capacitive connection between the separate carbon granules. This will lead to a strong capacitive shunting effect at higher frequencies. Some curves are shown in Figure 11.

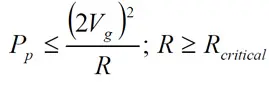

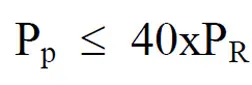

If the capacitive frequency dependence is great the inductance is the smaller. The current passes through an infinite number of branches connected in parallel which altogether creates a negligible inductance inside the resistor body. This, however, doesn’t mean that we have found the ideal component for pulse loads even if we occasionally may see such assertions. Only low resistance values, where the resistor body consists mainly of pure carbon, may correspond to such assertions. Otherwise strong surge currents might damage the uncountable contact spots in the current paths. The pulse power Pp should be limited to

Caution! Parts from less serious manufactures may have a fire risk at improper overload conditions.

The temperature dependence is strongly non-linear. Table 6.

Current noise and stability are poor. The method to adjust low or decreasing resistance values by baking gives only temporary results. After some time the value is too low again. As said before, there are few reasons for choosing a carbon composition resistor.

Conductive Plastic Resistors

Of the fundamentally important resistance materials only one remains to be mentioned: the conductive plastic. It is closely related to the carbon composition. Actually it belongs to the potentiometers but for consistency reasons is presented in this article.

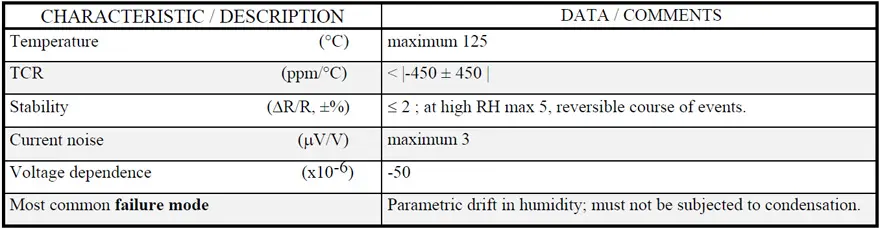

If carbon powder and thermosetting plastic together with a binder are mixed together and molded we get a so called conductive plastic. It is used above all in servo potentiometers due to its low friction and excellent wear resistance. The resistance stability is fairly good provided it is not subjected to too high relative humidity or condensation.