This blog article written by Pablo Blázquez, Frenetic power electronic engineer, discusses planar transformers for flyback and forward converters with a general overview of the basics and a comparison between planar and traditional transformers.

Flyback and Forward converters are topologies used for low-medium power isolated applications. The Flyback is more suitable for high-voltage outputs, while the forward has the disadvantage of having an extra inductor on the output and is not well suited for high-voltage outputs.

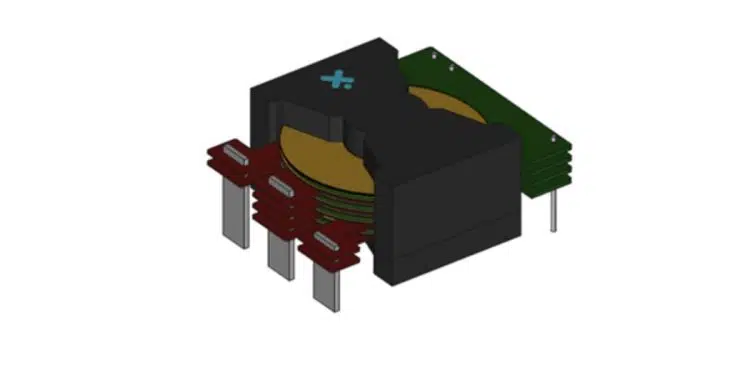

We will analyse how planar transformers can give us more flexibility with these converters when we have space constraints, with a lower leakage inductance, incredibly good repeatability, and great thermal characteristics.

Flyback and Forward considerations

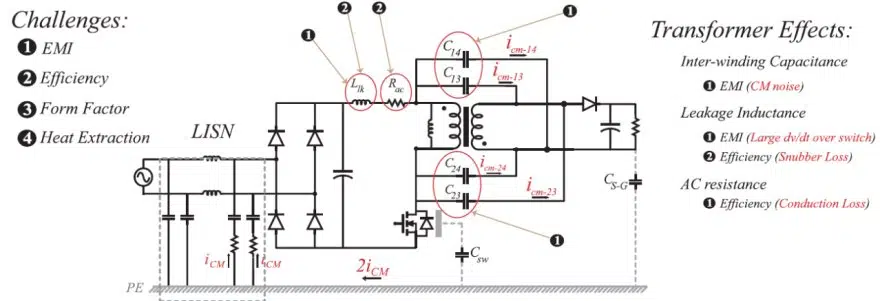

In paper [1] is mentioned that, while designing a Flyback or Forward converter, we will normally face several challenges:

- EMI (Electromagnetic Interferences) losses

- Efficiency

- Form factor

- Heat extraction

Large leakage inductances affect the performance of the transformer creating large voltage spikes on the switch, leading us to use higher-rated voltage switches. Also, this high voltage spike creates common mode noise in the parasitic interwinding capacitance.

The form factor of the transformer, normally the height, will define the size of the converter as well as the places where it can be positioned. For example, a traditional flyback will be difficult to fit in certain low-profile applications, such as headphones or flat TVs.

The higher height is a problem regarding heat transfer, as it generates higher thermal resistance. This happens as the contact surface is more distributed in the planar transformer than in the wound transformer that is more concentrated in one place.

Planar Transformers or Traditional Transformers?

Traditional Transformers

If we compare planar transformers with traditional ones, we will use less space in the PCB footprint in the wound transformers. So unless power dissipation is a problem, designers will normally use standard transformers.

Winding in traditional transformers is also simple and we know how to do it. The time needed for creating a design and wounding is much lower in traditional transformers.

We will have higher temperatures, as the traditional transformers are limited by the amount of W that the core can dissipate due to the temperature rise. This normally requires forced convection to address this problem, while planar transformers can work with higher W in the core and therefore, we can reduce the losses in the windings. This will give us the possibility of using a heatsink instead of a fan.

Overall, wound transformers must face all the design considerations in Flyback and Forward converters, but we know how to design and create designs incredibly fast.

Planar Transformers

Planar magnetics are chosen for the high-frequency spectrum because they offer a small number of turns (compared with wound transformers) and extremely low resistance.

Planar transformers can enhance the performance of these converters, as we will be able to have lower height, weight, and leakage inductance. We will have wider surface areas than traditional E, EC, or EP cores. This means that we will be able to have fewer turns, as well as being able to have lower DC resistance.

Regarding the winding, it is difficult to enter a wire that can handle all this power in such a small space, but the planar transformers’ rigid structure allows us to use PCB windings instead of bobbins. This way we can have lower-profile transformers, as well as a great level of repeatability, as the printed circuit nature of the windings. We will also be able to integrate into the converter´s PCB the windings for having an even more compact design.

However, there are some drawbacks when designing a planar transformer. We can have problems with safety requirements. Using PCB FR4 can generate problems in the external layer of the windings, top and bottom, and we will need to use traditional isolation methods, like Nomex, to meet those safety requirements. At least in the internal layers we are covered. Multiple layers can be problematic in the design phase, especially if thick copper plating is required.

Another problem that we will face when designing with Planar transformers is the EMI losses. The flux must travel through the side wall of the core so, the flux on the side will be increased. However, the flux density that we will be having on the central leg will be much lower than in the wound transformer.

Planar transformers are an interesting option for some applications: they have a more complex design than traditional transformers, but can help us in some situations.

Summary

Planar transformer advantages and cons:

Benefits

- Planar transformers give us extremely low leakage and AC resistance

- Overall size of the converter is reduced

- Better heat transfer

Limitation

- Large interwinding capacitance (Increased CM noise) and causes EMI problems

References

[1] Ali Saket, M. Ordonez, N. Shafiei. (2018). Planar Transformers with Near-Zero Common-Mode Noise for Flyback and Forward Converters (Vol n. º 33) [IEEE]. IEEE Transactions on power electronics.

[2] Achieving Higher Efficiency Using Planar Flyback Transformers for High Voltage AC/DC Converters. Bourns.

[3] “What’s the Difference Between Conventional and Planar Switching Power Transformers? “ Passive Components Blog