AVX Corporation released technical paper “Tantalum Polymer vs Aluminum Polymer Performance as an Output Filter Capacitor for Miniature Switching Power Supplies” written by Ron Demcko, Ashley Stanziola and Daniel West.

Abstract:

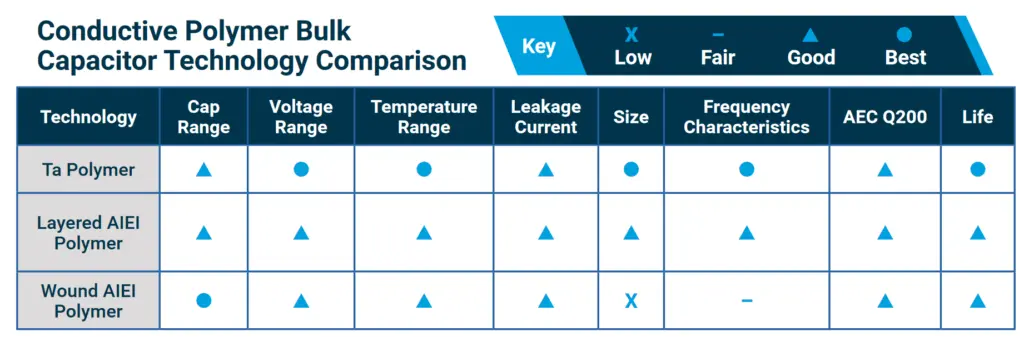

Engineers have questioned the impact performance of converting Aluminum Polymer capacitors to Tantalum Polymer capacitors in applications where MLCCs are present on the output filter ‘bank’ of a small switching power supply. The reasons for designers to convert to Tantalum Polymer capacitors in the design ranged from long term reliability and stability to availability/delivery and company specific design guidelines.

This investigation is intended to compare the interchangeability of Tantalum Polymer Capacitors in a design with the original Aluminum Polymer capacitors. The data collected was the measured output voltage ripple on a highly utilized circuit/chipset under a specific conditions of an end user. Comparisons between Aluminum Polymer Electrolytic and Tantalum Polymer Electrolytic technologies are made.

Summary

- The testing performed proves that Conductive Tantalum Polymer capacitors can effectively compete with and replace Aluminum Polymer capacitors in output filter applications.

- Conductive Tantalum Polymer capacitors offer designers multiple advantages ranging from ease of use due to wide case sizes and under-tab lead frame options to exceptional reliability.

- Conductive Tantalum Polymer Capacitors have characteristics such as, case sizes as small as 0402, part volume as low as 0.363mm3, and weight as low as 1mg; which are ideal for weight sensitive applications. Modern day cores such as microcontrollers, microprocessors and FPGA frequently utilize these devices as miniature bulk filter caps.

- Conductive Tantalum Polymer capacitors reliability is better than 1%/1000 hours at 85°C with 100mΩ series impedance at 60% confidence level. Additionally, several families of enhanced reliability devices exist such as AEC Q200 auto grade and European Space Agency qualified series.