Due to a spike in COVID-19 cases, Malaysia has imposed indefinite extensions to movement control and a stricter lockdown in Selangor and parts of Kuala Lumpur. The industrial zones in Bandar Indahpura and Senai are in a 14-day total lockdown where economic activities are suspended.

Some of the Japanese and Taiwanese manufacturers of passive component in these areas have been forced to suspend production. Resistor supplier Ralec’s facilities there will remain closed until July 22 and projects a 30% decline in production capacity for July, according to its parent company Kaimei Electronics.

Kamaya under Walsin Technology said it has a plant in Perak, but restrictions there have been relaxed and its production has been almost unaffected.

Despite reductions in workforce, many manufacturers are still able to maintain over 80% in utilization rates. However, a 2-week total lockdown is still a challenge for some. Finished products with already low inventory will go down fast. A two-week lockdown will be manageble for bigger makers, but it will be a problem beyond that duration.

Inductor supplier ABC Taiwan Electronics (ATEC) said restrictions on the number of workers on duty and working hours are ever-changing, which inevitably has impacted capacity. Its production plant in Selangor is currently operating on only 60% of workforce.

Impact on the supply chain varies from product to product. Standard chip resistors are supplied by a large number of qualified suppliers; EMS and ODM usually have at least three to four suppliers, industry sources said.

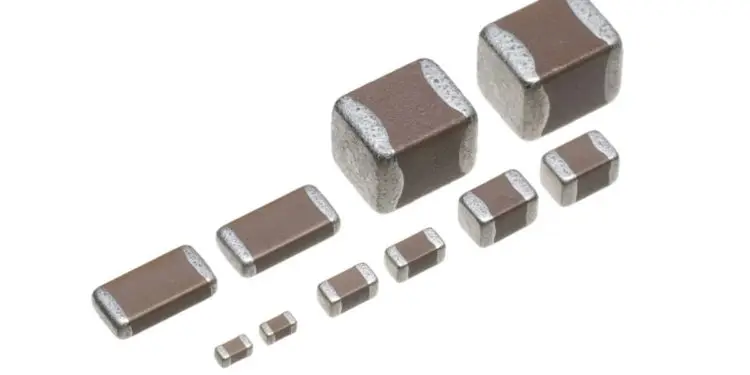

But capacitors, including aluminum capacitor and multilayer ceramic capacitor (MLCC), have seen tighter supply, with lead times extending to as long as over 24 weeks, the sources added.