This post provides a comprehensive technical explanation of connector coding, focusing on the industry-standard M12 and its compact variant M8, complete with specifications, usage cases, and engineering context.

Key Takeaways

- This article explains connector coding with a focus on M12 and M8 connectors, emphasizing their importance in industrial automation.

- Connector coding prevents mismating, ensures reliability, saves time, and enhances safety during installations and maintenance.

- M12 connectors offer various coding types for different applications, while M8 connectors are suitable for space-constrained environments.

- Coding benefits include reliable communication in industrial networks and protection against environmental factors.

- Selecting the correct connector involves considering voltage, signal type, mechanical constraints, and environmental requirements.

Introduction

Circular connectors like M12 and M8 are fundamental in industrial automation, robotics, and transportation. Coding systems ensure safety, compatibility, and reliability by preventing mismating and supporting quick, error-free installation.

Why Connector Coding Matters

Connector coding is essential for daily operations involving installation, maintenance, and upgrades. Each time a connector is removed or replaced, incorrect mating can cause failures, downtime, or hazards. Coding addresses this by:

- Preventing mismating: Unique pin/socket/keying layouts only allow correct matching.

- Ensuring reliability: Mechanical features align connectors accurately before locking.

- Saving time: Field technicians can connect devices safely, reducing installation errors.

- Enhancing safety: Cross-connections, short circuits, and voltage errors are avoided.

Coding is vital in all industries that require error-free signal, data, and power transmission.

M12 Connector Coding – Technical Overview

M12 connectors have become a leading choice for automation due to their compact size, durability, and broad coding selection. The key coding types and their major properties are outlined below:

| Type | Current | Voltage | Protection | Contacts | Applications |

|---|---|---|---|---|---|

| A-coded | 1.5–8A | 30–250VAC | IP67/68/69K | 3–12 | Sensors, CAN, DeviceNet, DC Power |

| B-coded | 4A | 60–250VAC | IP67/68 | 4–5 | PROFIBUS DP |

| D-coded | 4A | 250VAC | IP67 | 4 | Ethernet, EtherCAT, PROFINET, Sercos |

| X-coded | 0.5A | 50VAC/60VDC | IP67 | 8 | High-Speed Ethernet up to 10 Gbit/s |

| S-coded | 12A | 630VAC | IP67 | 3+PE | AC Power Supply |

| K-coded | 12A | 630VAC | IP67 | 4+PE | AC Power Supply (higher pole count) |

| L-coded | 16A | 63VDC | IP67 | 4–FE | DC Power Supply, PROFINET |

| T-coded | 12A | 60VDC | IP67 | 4 | DC Power Supply |

| US-coded | 4A | 250VAC | IP67 | 3–5 | Signal |

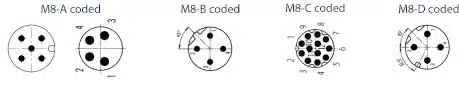

M8 Connector Coding – Technical Overview

M8 connectors are ideal for space-constrained environments and miniaturized machinery. Their coding types match the diversity of industrial requirements for signal, data, and low-power applications.

| Type | Current | Voltage | Protection | Contacts | Applications |

|---|---|---|---|---|---|

| A-coded | 1.5–4A | 30–60VAC | IP65/67/68/69K | 3–8 | Power, Signal, CAN, DeviceNet |

| B-coded | 3A | 30–60VAC | IP67/68/69K | 5 | PROFIBUS DP |

| C-coded | 1A | 30–32VAC | IP67 | 12 | Power, Signal |

| D-coded | 1.5–4A | 50–63VAC | IP67 | 4 | Ethernet, PROFINET |

Coding Benefits & Use Cases

- Fieldbus and Ethernet: M12 D-coded and X-coded ensure communication reliability for PROFIBUS, PROFINET, EtherCAT, and high-speed Ethernet networks up to 10 Gbit/s.

- Power separation: Codings like T, L, S, K in M12 and A, C in M8 ensure proper voltage levels and protect sensitive electronics.

- Industrial sensors: M8 A-coded and M12 A-coded widely used for field device power and signal connections.

- Harsh environments: IP67–IP69K protection maintains integrity against dust, water, and vibration.

Color coding and mechanical keying in these connectors facilitate easy, error-proof deployment by visual and tactile feedback, critical for technicians working under time constraints.

Practical Engineering Selection

When specifying a connector, engineers should reference the coding charts above and consider:

- Voltage and current levels (match rating to application)

- Signal/data type (fieldbus vs. power delivery)

- Mechanical constraints (pin count, housing size)

- Environmental requirements (IP protection, temperature)

Correct coding selection prevents device damage, system errors, and future-proofs installations for expansions or upgrades.

Conclusion

Connector coding is a subtle but crucial part of system engineering in industrial automation. By employing standardized coding schemes—especially in M12 and M8 connectors—engineers gain robust, safe, and reliable interconnect solutions. Coding ensures error-free installation, operational safety, and compatibility for applications as diverse as high-speed communication, AC/DC power distribution, and miniature sensor networks. Adhering to appropriate coding practices is essential for long-lasting, efficient operations in all automation and control systems.

FAQ – Coding in Circular Connectors

Circular connectors use coding systems to prevent mismatching, guarantee correct mating, and ensure safe, reliable connections in industrial and automation applications.

A coded connector features unique pin, socket, and mechanical keying layouts to ensure that only the correct plug fits the correct socket, preventing error-prone connections.

A- and B-coding support sensor connections and data lines by ensuring correct orientation and application-specific compatibility, thus reducing the risk of signal interference or equipment damage.

Yes, M12 connectors are available in coding types suitable for both power (e.g., S, K, L, T) and data (e.g., D, X), letting engineers safely combine different transmission needs within one robust format.

M8 connectors are smaller and ideal for compact applications but offer fewer coding types than M12. M12 offers a broader variety of codings for high-power, data, and sensor applications.

A-coding is used for sensors and DC power; B-coding for PROFIBUS; D-coding for Ethernet up to 100 Mbit/s; X-coding for high-speed Ethernet up to 10 Gbit/s.