source: Intelligent Aerospace article

By Dan Friedlander

Retired following 44 years in component engineering

The road from the use of space/military electrical, electronic, and electromechanical (EEE) components in space applications to the use of commercial off-the-shelf (COTS) components in space applications is not smooth. Several barriers must be overcome, including: fear of risk, resistance to change, storage, obsolescence, counterfeits, and lead-free barriers.

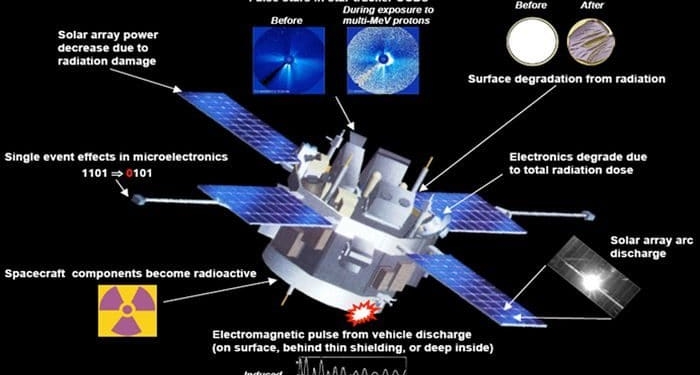

These manmade barriers were challenges also encountered by military users during the successful transition to the use of COTS components in military applications. The main natural space environmental barrier to be overcome is the radiation threat to the active electronic components. Among many other threats to be addressed, the critical radiation issues have been addressed successfully from the start of the space activities. The figure below summarizes the major space environment hazards, including those relevant to electronic components.

The Radiation Hardness Assurance (RHA) plan is aimed at ensuring that “the radiation withstanding of a given component is higher than the actual expected radiation level in space.” To ensure the above, components radiation tests are performed. The testing activities are expensive and make up a significant part of the component ownership cost.

The transition to usage of COTS components in space applications makes the life more difficult, because of a lack of existing relevant radiation database. The radiation barrier is not impassable.

Radiation testing

The radiation testing methodology is a well known, standardized one. It is applicable also to COTS components. As mentioned above, radiation testing of electronic components is expensive, especially those resorting to heavy ion or proton accelerators. To keep radiation testing at an affordable cost level, the component selection process shall address the radiation issue through a theoretical, deep analysis of the given candidates.

The decision making of what (if any) types of actual radiation testing are relevant to a specific component requires certain information (sometimes not published).

- Component technology/process CMOS, EPI CMOS, SOI, BICMOS, BIPOLAR, etc.; different technologies/processes are sensitive to different radiation threats.

- Component category; e.g., IC, MOSFET, etc.; each category needing different radiation tests.

- Foundry identity.

- Die revision.

- Existing radiation test results.

- Space heritage.

Although the radiation testing is standardized, the criteria for actually performing a Radiation Lot Acceptance Test (RLAT) may differ across the space industry. It is worth revisiting the criteria to relax the need for RLAT. The criteria should include lot homogeneity consideration and radiation margin consideration.

As mentioned above, the same radiation testing applies to COTS components. The radiation is threatening the dice and not the packages.

Radiation testing priorities

Radiation testing is an expensive, time-consuming activity. Successful radiation test results are not guaranteed, especially for components without known radiation data. An eventual test failure may have a significant negative impact on a space project schedule. Consequently, right priorities choice may save time and money.

The types of radiation threats consists of destructive ones and nondestructive ones.

The first priority for the radiation testing performance is the tests addressing destructive hazards. Relevant testing includes:

- SEL (Single Event Latch up),

- SEGR (Single Event Gate Rupture), and

- SEB (Single Event Burnout).

The second priority for the radiation testing performance is the tests addressing nondestructive hazards. Relevant testing includes:

- TID (Total Ionizing Dose),

- Displacement,

- SEU (Single Event Upset), and

- SET (Single Event Transient).

The terminology

The above terms are sometimes not fully understood and consequently misinterpreted:

“Space Qualified” is the quality level of the component. It does not mean automatically that such a component is suitable for use in any space application. The term itself does not address the radiation issues. Quality level “S” is one of the highest quality level designations and should not be automatically interpreted as “S” = “space”. There also other highest quality level designations, like “V” for QML ICs or “K” for QML hybrids or “B” for ESA.

A radiation hardness assurance (RHA) designator shall be added to identify a space

level, radiation specified component. Even if a space level, radiation specified components is selected, it is the user responsibility to verify if the radiation is specified at the right conditions.

For example, one may meet a spec specifying a radiation level (TID) of a bipolar component at High Dose Rate (HDR), instead of at the right Low Dose Rate (LDR), the bipolar component being consider ELDRS (Enhanced Low Dose Rate Sensitivity).

“Radiation Hardened” refers to a component that has been specifically designed and/or processed to withstand a given level of radiation (TID and/or SEE). The radiation characteristics are an integral part of the component specification and are guaranteed by the component manufacturer.

“Radiation Tolerant” components have been detected by radiation testing by the component manufacturer to be able to withstand a given level of radiation (TID and/or SEE). The radiation characteristics are an integral part of the component specification and are guaranteed by the component manufacturer.

In context of COTS components usage in space applications, the user may take the initiative to detect by radiation testing a given radiation tolerant component under his full responsibility.

It is not different from the way non-radiation-specified space/military-grade components have been dealt with for decades.

Radiation issues addressed by the commercial market

What could be the reason not to find in the market radiation-tolerant plastic encapsulated microcircuits (PEMs)? The availability security of officially preferred space/military grade hermetic components is critical. To cope with the global components’ market developments, new thinking is a must. The needed components availability and affordability are key factors to go ahead with future challenges posed by mega constellations, shrinking budgets, component manufacturers’ business decisions, etc.

Recently, the first signs of open-minded, realistic decisions were taken by at least two component manufacturers, namely:

- Intersil (now Renesas). They start to offer radiation-tolerant PEMs, based on the automotive methodology (one-time qualification). It is a good start, in spite of the resistance to change by the authorities responsible for the COTS penalizing official policy.

- Linear Technology (now Analog Devices). They talk about radiation-tolerant PEMs, but they are not willing to reply to a request for details of the methodology and a specific data sheet.

Lot homogeneity

One of the many anti-COTS arguments sounded by Resistance to Change Party Members (RCPM) is lot non-homogeneity. The lack of homogeneity, the state of being homogenous, leads to invalid radiation test results due to invalid sampling statistics. Literally, that is correct.

Nevertheless, as mentioned, new thinking is required.

Space-level components have wafer traceability, the best ensured lot homogeneity. However, there is no space project built exclusively with space level components. Military-level components are also used within the official space policy. As known, military-level components do not have wafer traceability. They have only date code traceability, like COTS.

The space community and leaders turn a blind eye on the lack of wafer traceability for traditionally acceptable military-level parts, but penalize COTS in space because of the same traceability issue.

In view of the improved process control (SPC) and high-volume statistics validity, the COTS components lot-to-lot and within-a-lot variation issue is worth revisiting. Anyway, although penalized as “last resort” by the official space policy, the validity of the COTS components sampling statistics is now officially recognized.

Mitigation activities and conclusion

Well-known mitigation methods – such as shielding, error detection, correction, etc. – are valid for COTS components.

The radiation barrier is not impassable for COTS components. It is not a show stopper.

Use of COTS components pose, at this starting stage, an obvious difficulty due to lack of radiation databases, lack of public information, questionable components manufacturers’ information release.

Radiation Testing is an expensive, time consuming, critical activity to be performed as soon as possible (ASAP).

The traditional radiation testing requirement shall be revisited, in view of the actual progress made due to improvement of technology/process/SPC, transition to high-volume production, transition to production outsourcing to big specialized foundries.

“Barriers are put in your way to see if what you want is really worth fighting for.” – unknown

Author biography

Dan Friedlander graduated Engineering School/Tel Aviv University with a degree in physics (1965-1969). He has 44 years of experience in Component Engineering at MBT/Israeli Aerospace Industries (1969 to 2013), as Head of components Engineering. As such, he was responsible for all aspects of EEE components – including policymaking, standardization at corporate level, approval, etc. – for military and space applications. Now retired, Friedlander is an industry consultancy (2013 to present).