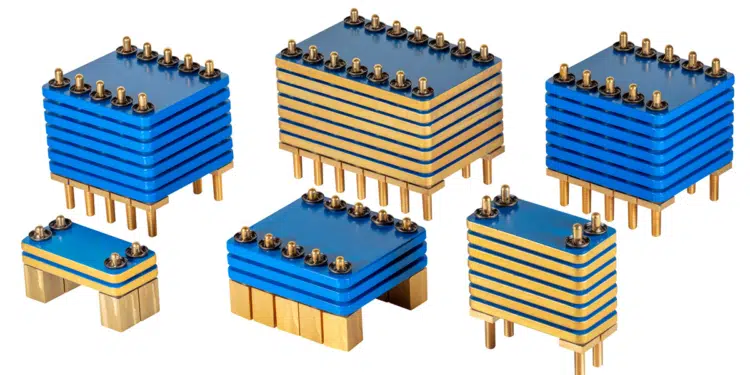

A customisable capacitor assembly for automotive, military and aerospace applications is now available from Knowles Precision Devices. The custom approach to large capacitor assembly offers capability and durability, while helping to maximise board space. The capacitor assemblies use the vertical space above the circuit board to achieve high capacitance and high voltage in a smaller area.

The large capacitor assemblies are custom built using large diameter pins that are low loss and ultra-stable dielectric. The pins are mechanically decoupled from ceramic elements, which allows the assembly to withstand severe mechanical shock, vibration and temperature variation.

“This custom approach to large capacitor assembly enables us to better accommodate the specific needs of our customers when they have a project that requires high capacitance and proven durability in a tight space,” said Steve Hopwood, senior applications engineer, Knowles Precision Devices. “By utilising the vertical space above the board, we can replace multi-chip assemblies where large arrays of multilayer ceramic capacitors are placed in parallel on a circuit board. While this approach has been used previously, traditional stacked caps can be susceptible to mechanical shock and vibration.”

The large capacitor assemblies – initially available in ultra-stable low-loss C0G dielectric – have a high capacitance range of 10nF to 3.9-microF and a voltage range from 500Vdc to 5000Vdc. The pins used are large enough to handle high ripple currents so that the capacitance does not drop with applied voltages or changes in temperature. The capacitor assemblies are tested to meet the demands of AEC-Q200 standards and are suitable for use in electric vehicle and resonant wireless charging systems.

Headquartered in Cazenovia, New York, Knowles Precision Devices produces a wide variety of highly engineered RF and microwave components, and high-performance capacitors for use in critical applications in military, medical, electric vehicle and 5G market segments.