Molex introduces MX-DaSH Modular Wire-to-Wire Connectors, combining power and signal terminals in a single, modular system to reduce wiring harness weight and complexity for automotive zonal architectures. This solution enhances design flexibility and supports global OEMs.

Molex, a global leader in electronics and connectivity innovation, proudly announces the launch of the MX-DaSH Modular Wire-to-Wire Connectors, the latest addition to its acclaimed MX-DaSH family.

These state-of-the-art connectors integrate power, signal, and high-speed data connectivity into a single system, offering unparalleled flexibility and efficiency for automotive design.

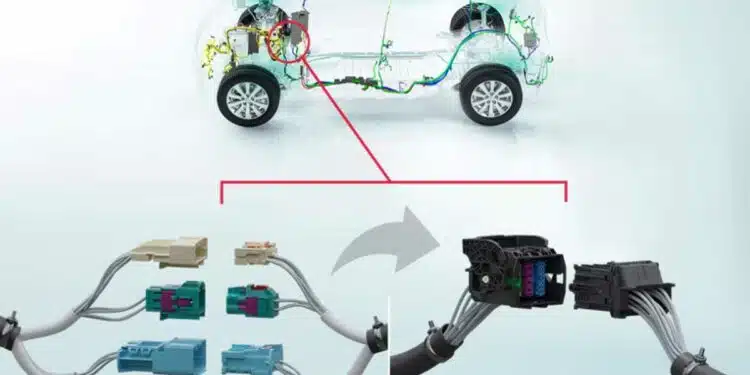

The MX-DaSH Modular connectors feature a versatile cartridge-based design housed in a single system, simplifying wiring and harness architecture. This innovation enhances automotive design flexibility, adaptability, and scalability across various vehicle models and applications.

“MX-DaSH Modular Wire-to-Wire Connectors address critical challenges in today’s automotive design processes, driven by rapid changes in electrical and electronic requirements,” stated Scott Whicker, Senior Vice President and President of Transportation Innovative Solutions at Molex. “Our cartridge-based design facilitates easy function mixing and reconfiguration, enabling faster development cycles and cost reductions.”

Designed for Zonal Architectures

Each MX-DaSH Modular connector is built on an unsealed, cartridge-based hybrid connectivity platform, consolidating multiple connectors and connection types into one. This approach reduces the number of unique parts, offering unmatched freedom to tackle specific automotive design challenges, accelerate upgrades, and significantly cut design and tooling time.

The “building block” approach optimizes vehicle harnesses, leading to substantial weight, size, and cost savings. Tailored for zonal architectures, MX-DaSH Modular connectors are perfect for high-content connection points, such as instrument panel-to-body harness connections, seat power and signal connections, and electrical/electronic architecture components. Engineers can easily change cartridges within the housing, allowing for seamless feature additions or pin and cartridge swaps to meet evolving architecture needs.

Global Adoption and Chinese Market Impact

Localized manufacturing and compatibility with industry-standard terminals are driving global adoption of MX-DaSH Modular connectors, while mitigating global supply chain challenges. The connectors adhere to USCAR2 performance specifications for automotive electrical connector systems and USCAR49 specifications for miniature automotive coaxial connectors.

China, the largest automotive market and a hub for innovation in electric vehicles (EVs) and Advanced Driver-Assistance Systems (ADAS), is a key testing ground for next-generation automotive technologies, including Molex solutions. A regional version of the MX-DaSH Modular connector will be featured in MY26 cars in China, addressing the unique cost, packaging, and expedited time-to-market requirements of Chinese automotive OEMs.

Additionally, other automotive manufacturers in North America and Europe are deploying these new modular connectors, with MY28 vehicle designs expected to incorporate MX-DaSH Modular Wire-to-Wire and Wire-to-Board Connectors.

Automation-Friendly and Reliability-Focused

The MX-DaSH Modular connector’s automation-friendly design supports precise automated assembly operations, enhancing manufacturing efficiency and quality while reducing labor costs. Positive-locking features, blade stabilization, and vibration resistance further enhance reliability by preventing inadvertent disconnection in demanding automotive environments. Molex’s robust engineering support, extensive quality control, and range of versatile, customizable solutions solidify its role as a unique resource for improving vehicle wiring performance and reliability.

Product Availability

Molex MX-DaSH Modular Wire-to-Wire Connectors are now available, offering unprecedented design freedom and flexibility to meet the rapidly increasing data, power, and high-speed signal requirements in today’s vehicles. The connectors support a maximum pin count of 70 circuits, with the following maximum circuit counts per cartridge: 26 circuits for 0.50mm (CTX50) cartridges, 14 circuits for 1.20mm cartridges, 4 circuits for 2.80mm cartridges, and 3 circuits for 4.80 and 6.30mm cartridges.