Non-linear resistors are resistive components, where its resistance is not behaving linearly with parameters such as voltage, current (varistors), temperature (thermistors) or it depends to previous stage (memristors).

The non-linear resistance behavior is successfully use to get specific features like sensors, limiters, ESD protection, self-balancing temperature stabilisation etc. using still a relatively simple and reliable passive component.

NTC Thermistors

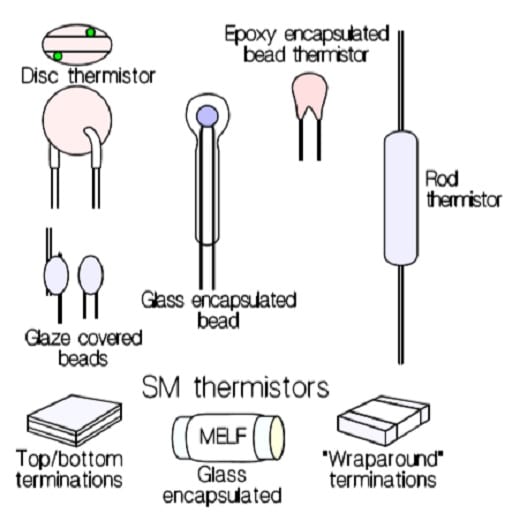

Simplified, the thermistor material consists of doped granule compounds containing various oxides that by means of binders have been pressed to a desired shape and then sintered. The terminals either are inserted into the resistor body or soldered to metallized surfaces. There are a number of encapsulation types.

Designs

Thermistors exist as rods, discs, beads covered with lacquer, epoxy, glaze or melted glass and as SMDs.

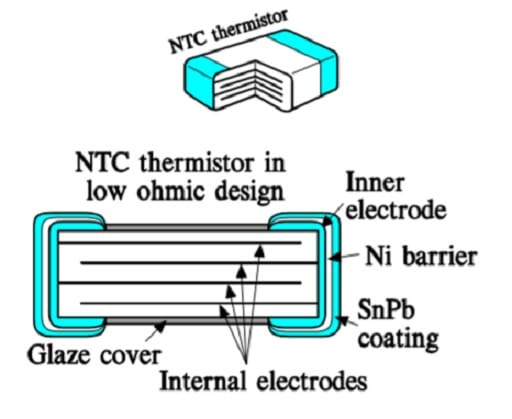

SMD thermistors in low ohmic designs are made with a number of internal electrodes as shown in Figure 2. The reduced resistance is achieved by a construction that connect “resistor elements” in parallel inside the thermistor body.

Temperature Dependence and Tolerances

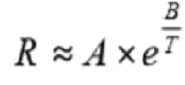

NTC stands for negative TCR (Negative Temperature Coefficient). The temperature dependence is strong and exponential and follows the formula

The material constant A determines the resistance and B its temperature dependence, i.e. the slope of the resistance – temperature curve. T means the temperature in Kelvin (°C + 273). If we apply the formula [1] on a reference temperature T0 and a general temperature T and combine the two expressions we obtain the formula

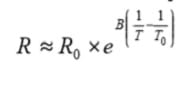

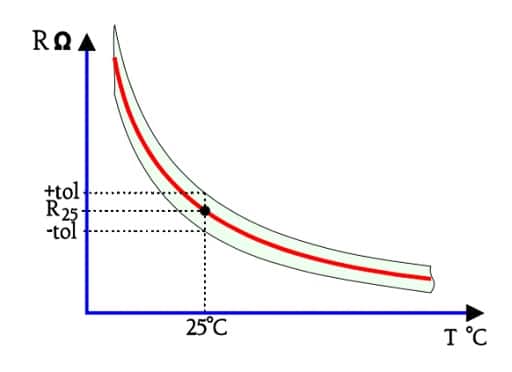

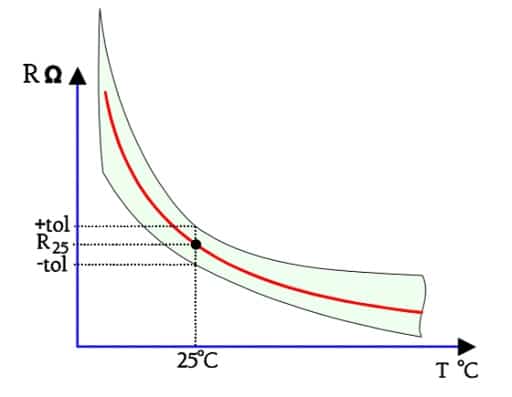

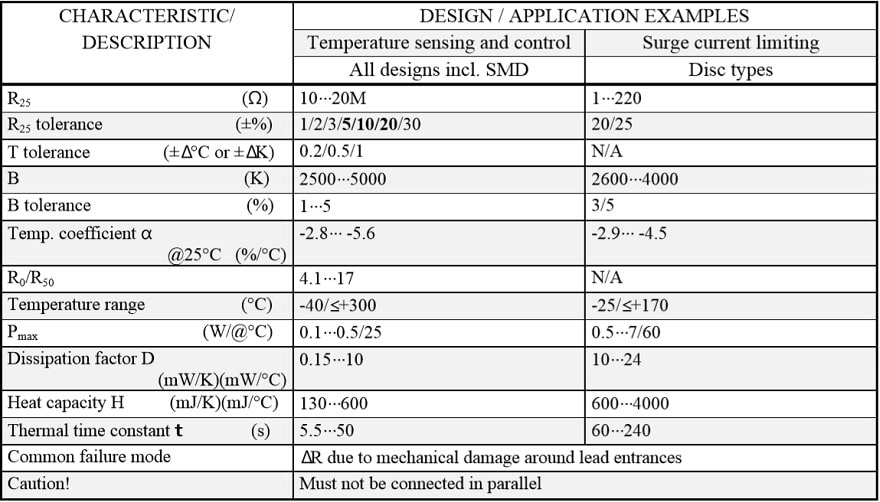

The constant B generally is determined by measurements at 25 and 50 °C. It usually has values between 2500 and 5000. The value varies a little with temperature. Hence the ≈ symbol in the formulas. The thermistor material shrinks strongly during the sintering process which causes great difficulties keeping the tolerances on both the R25 and the B value within specified limits. The B value is stated with tolerances that usually are 5 %. The reference value R0 relates to 20 or 25 °C and has tolerances of 5, 10 or 20 %. However, by sawing already sintered chips to close dimensions one increases the accuracy considerably. R25 tolerances of 0.2⋅⋅⋅1 % no longer are exclusive, nor are tolerance of 1 % on the B value. The result of these superimposed tolerances looks like the illustrations in Figures 3. to 5.

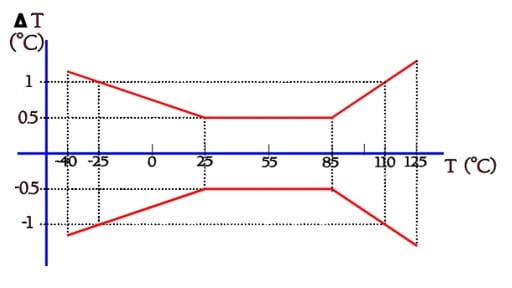

For more accurate applications two or more points on the Resistance/Temperature curve – abbreviated R/T curve – are specified, a so called curve-tracking application. The B tolerances then are of less importance. The tolerances of such a two or three point sensor may be stated either as a resistance deviation ∆R in percent of R or as a temperature deviation ∆T in °C, at the temperatures in question (Figure 6). In the latter case we have to calculate ∆R by means of the temperature coefficient α in the Formula [3].

Slope and Temperature coefficient

The slope of the R/T curve for an NTC thermistor is determined by the B value. Sometimes the temperature coefficient a (or also called α) is also specified. If we derive the expression in Equation [1] we obtain:

Compared to general resistor TCR formula, where TCR = 1/R x ∆R/∆T, we find the same basic expression as for α. As follows from Equation [3] α varies strongly with temperature. Around 25 °C α usually has values between –3 and –5.5%/°C. Yet another way of specifying the slope of the R/T curve is by using resistance ratios. For example the ratios of R0/R50 or R25/R125 are compared. The ratios are stated with tolerances.

Self-Heating Effects

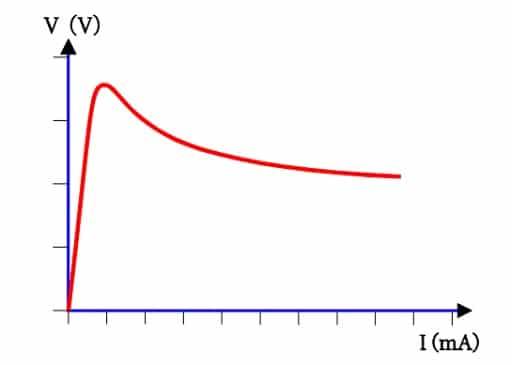

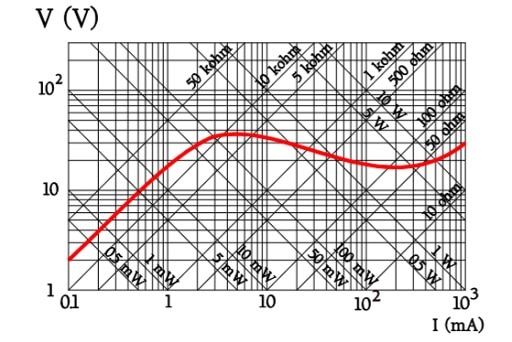

The self-heating of the NTC thermistor influences the resistance. If we apply a voltage over the thermistor the current at the beginning rises linearly according to Ohm’s law. But as soon as the internal power generates palpable heat the resistance starts decreasing. Further voltage rises gradually force resistance reductions that occur faster than the current increases. The V/I curve starts declining (Figures 7. and 8.).

The example in Figure 8. helps us realize how the parameters V, I, P and R belong together.

Thermal Cooling Time Constant, Heat Capacity and Dissipation Factor

Another two parameters are associated with Figure 8., namely, time and temperature. Size, shape and surrounding medium influence the velocity with which the temperature is changed. A measure of the change velocity is the thermal time constant, t. It is specified for an in-still-air freely mounted thermistor body under zero power conditions and is defined as the time required for the temperature to change by 63.2% – exactly (1-1/e) – of the difference ∆T between the initial and final body temperature, T0 respectively T∞ (Figure 9).

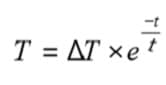

With designations from Figure 9. the thermistor temperature can be written:

t also can be deduced from two material constants, the heat capacity H (J/°C) and the dissipation factor D (mW/°C).

The heat capacity describes how many Joules (Ws) that have to be conveyed to the thermistor body in order to rise its mean temperature by 1 °C. The dissipation factor D is expressed in mW/°C (or mW/K) and is specified as the power that raises the mean temperature of a thermistor body by 1 °C (or 1 K) when freely mounted in still air. The power dissipation capability, of course, can be increased by means of fans, heat sinks or another cooling medium, for example a suitable liquid. In that case one obtains a practical time constant. If the thermistor is placed in a suitable liquid the time constant is decreased drastically. Among other things this is utilized at production control. The thermistor is immersed into a precise temperature controlled bath and thus in a very short time is conveyed to the stable measurement temperature.

Thermistor Application / Choice of Type

We can distinguish three main groups of applications:

- The temperature dependence of resistance R = f(T) is utilized. The temperature then may be determined

- either by the surroundings

- or by the internal power of the thermistor.

- The time dependence R = f(t) is utilized, i.e. we make use of the inherent thermal inertia of the material.

- The typical NTC characteristics of the material is utilized. When we choose a thermistor we have to consider the following requirements

- Environment and encapsulation requirements. Glass, glaze cover, lacquer/epoxy, no encapsulation.

- Temperature range.

- Shape and design. Chip/SMD, rod, disc or bead thermistor.

- Soldering, spot welding or gluing.

- Reference temperature R25 and temperature coefficient α (-B/T2).

- Tolerance requirements on R25 and B value. Is it a point-matching or a curve-tracking R/T application?

- Power dissipation a) without perceptible heating. b) with maximum change in resistance value.

- Thermal time constant τ.

Linearizing the R/T characteristic

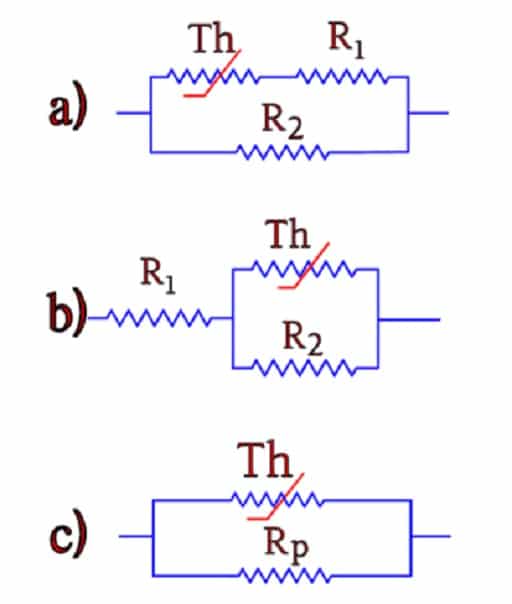

If we want a temperature dependence with a particular slope of the R/T characteristic over a broader temperature range, it is usually difficult to find a suitable curve shape. However, by means of fixed resistors combined with the thermistor it is possible to adjust the R/T curve in a desired direction. Figure 10. shows some examples of simple circuits to do this.

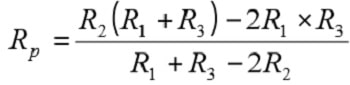

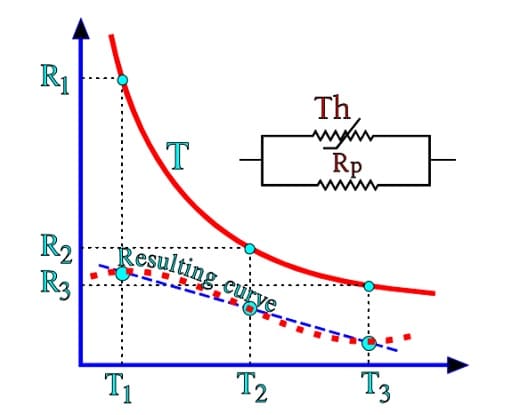

With alternative c) one may obtain an interesting solution by dimensioning Rp according to Equation [6] below. The resulting parallel resistance gives a curve that intersects a straight line in three points, as shown in Figure 11.

Failure Modes

Thermistors often have very small sizes and high resistance values. They are sensitive to every “disturbance” in the material. An exposed part of the body is the terminal area, especially for small sizes. If the body isn’t encapsulated in such a manner that any lead bendings are mechanically unloaded before entrance to the thermistor body, it is easy to create small cracks around the lead entrance. With those cracks, the resistance is changed; there also is left a way for moisture and liquids to penetrate the body.

Glaze covered beads and uncoated discs with terminals soldered direct on top of metallized pads are examples of vulnerable designs. Uncoated disc thermistors are not recommended for use in conductive liquids and aggressive gases. The sintered material sometimes undergoes settlings in the crystalline structure. Such events manifest themselves as sudden resistance changes in the magnitude of 3 to 10 % and may be released by heat, temperature changes and mechanical shocks. The failure rate for non-treated delivery lots varies between 30 to 60 %. The cure is a burn-in process that usually is performed as a heat treatment.

Bead thermistors encapsulated in a melted glass body often have small sizes and corresponding thin leads, consisting of alloys that often are difficult to solder. In such events leads intended for spot welding may be the only solution. Caution. Never try to connect NTC thermistors in parallel in order to increase the power dissipation capability. The thermistor that for the moment has the lowest resistance will get a higher current load, a stronger self-heating, a greater resistance decrease, an even higher current load etc., until the avalanche effect will destroy the component.

Reliability

The reliability of NTC thermistors today is regarded as good. It depends not least on serious manufacturers with Statistical Process Control (SPC) based programs for manufacture and verified type qualifications. If we determine that the components are burn-in treated and if we purchase them with hermetic seals, i.e. glass or glass/metal housings, the reliability of such thermistors should be classified in the same group as fixed metallized film resistors.

SMD thermistors eliminate some of the problems connected with sensitive lead terminals. In the beginning there were some solderability problems but today they may be regarded as overcome. We now have got a component that structurally resembles the ceramic chip capacitor, however, with fewer sources of error. The stratified low resistance variant has its electrodes embedded in the material and may from a reliability aspect be comparable to the homogeneous type.

Read more about thermistors measurement system configurations, NTC vs PTC thermistors vs RTD resistor temperature detectors in this article: Thermistor-Based Temperature Sensing System Explained (passive-components.eu)

Nuclear radiation

Tests with radioactive radiation in the form of neutron, β and γ radiation show that thermistors are capable of withstanding high intensities without any effects on the characteristics.

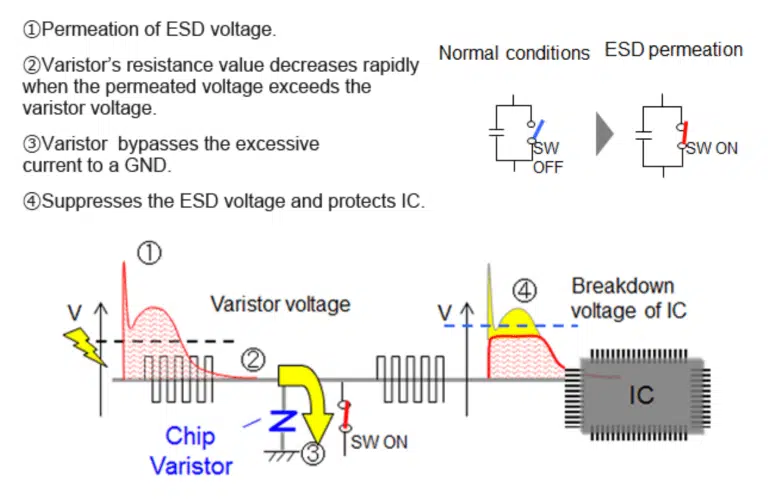

Varistors

Varistor stands for Variable Resistor. It’s a voltage nonlinear resistor/voltage-dependent resistor. It is an element that changes its resistance value depending on applied voltage. This feature is mostly used to protect electronic devices from the abnormal voltage, such as lightning surge and static electricity. Unlike thermistors it has no practical time delay of its function.

Function and Design

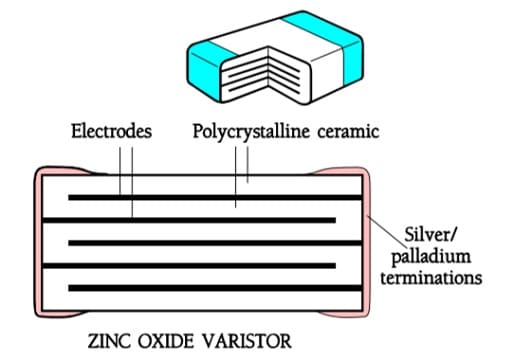

Just as thermistors the varistor is fabricated from a compressed and sintered powder compound that consists of silicon carbide (SiC) or zinc oxide (ZnO). The ZnO varistor has superior characteristics and predominates today all manufacture. This section deals with ZnO varistors only. If we sinter zinc oxide together with other metal oxide additives there is formed a polycrystalline ceramic. In the intergranular boundaries of the zinc oxide grains are formed P-N junctions with semiconductor characteristics – so called Double Schottky Barriers – with rectifying characteristics. Each ZnO grain with adherent boundaries acts as a miniature varistor with a symmetrical V/I characteristic. The grain compound can be regarded as a conglomerate of “microvaristors” connected in series and parallel. Thus the load and energy absorption capability in that way will be totally superior to conventional semiconducting elements. There the power generation exclusively will occur in the thin P-N boundary while in the varistor it takes place in all the microvaristors distributed homogeneously in the whole body.

The V/I characteristic of an elementary varistor may look like the one in Figure 12. Other manufacturers may have somewhat modified voltage values. The number of microvaristors connected in series and parallel determines the electrical characteristics of the varistor. If we connect 10 grains in series, with a characteristic according to the figure, we get a varistor with the thickness of 10 grains and a varistor voltage of 30 V. Varistors are shaped and encapsulated approximately as the thermistors.

Of the different designs discs are predominant, with radial leads and a variety of encapsulations, or with whole, metallized surfaces intended for series connection by piling the separate varistors. Encapsulations, for example lacquer or the like, require high tensional stability and resistance against washing agents. Of the uncovered types a certain tubular design intended for connectors should also be mentioned At manufacturing the goal is a grain compound with a regular structure, especially in high voltage/ high energy varistors.

An irregular structure impedes the heat conduction and may lead to an uneven current distribution and occurring Hot Spots and local degradation of the material. In low voltage applications homogeneity is of vital importance. The combination of a multi-electrode construction and small, uniform grains has created the multilayer varistor (MLV), preferably used as SMD, intended for low voltage applications.

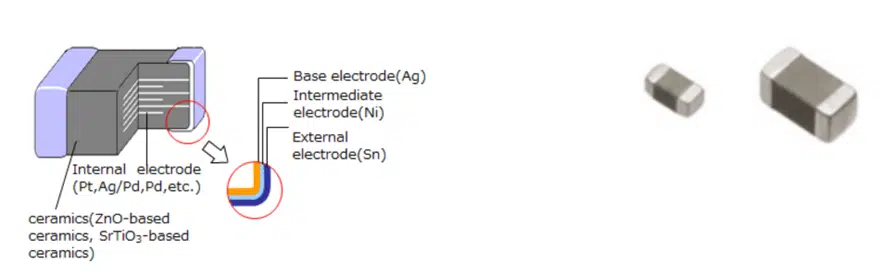

These MLVs are manufactured in a similar way as multilayer ceramics (MLCCs). The electrodes are screenprinted with a thick film ink on the zinc oxide layers, the layers are stacked to a pile with the desired number of layers. The stack then is sintered to a monolithic body and finally supplied with terminations that are fired onto the body ends. Silver or silver/palladium is used as termination metal in old and military styles (Figure 13. and 14.) while BME nickel electrodes are the mass volume types today. Plating of a nickel barrier requires due to the conducting zinc oxide special processes which deviate from the conventional electroplating.

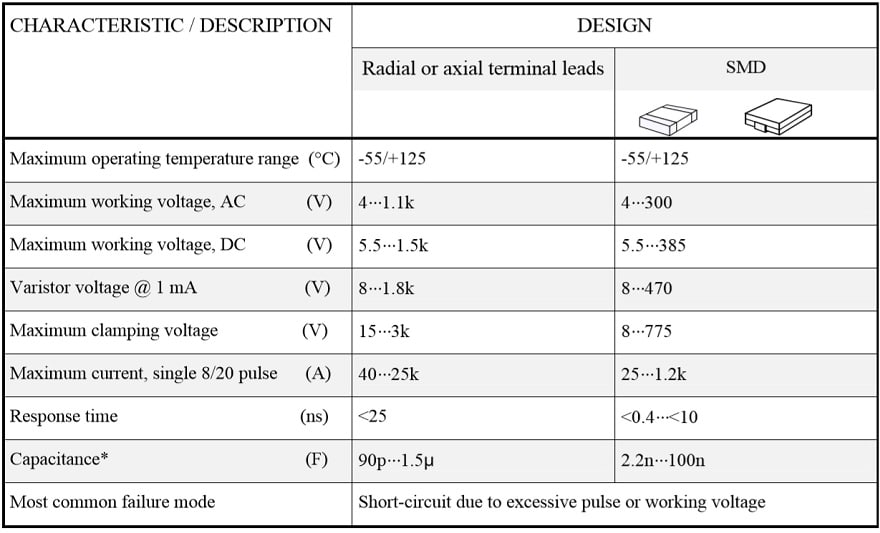

Multilayer SMD designs are produced in EIA sizes from 0201 to 2220.

Some Definitions

Maximum working voltage

Maximum working voltage = the maximum voltage which continuously may be applied across the varistor.

Varistor voltage

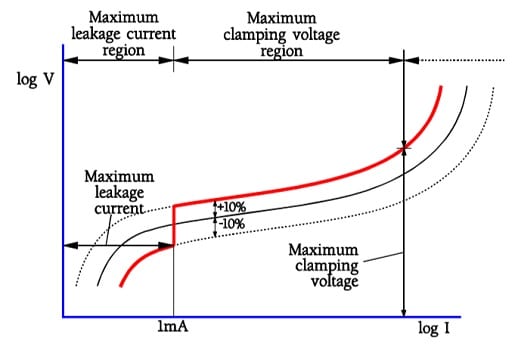

The varistor voltage = the voltage across the varistor when a current of 1 mA is passed through the body.

Maximum clamping voltage

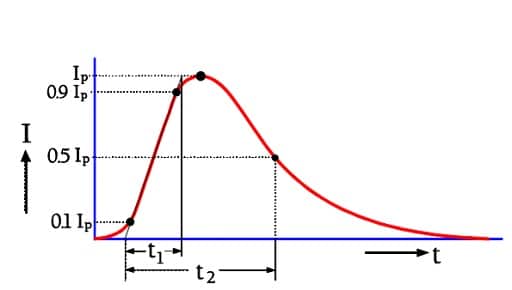

By maximum clamping voltage we mean the peak voltage across the varistor when it is subjected to a specified peak pulse current with a specified waveform. A common test pulse is the IEC specified so called 8/20 pulse with a specified current intensity.

Maximum transient peak current

The maximum current that may be allowed through a varistor depends on pulse shape and pulse width, repetition frequency and number of cycles. A starting point for the pulse capability is given by the maximum peak current of 8/20 shape that changes the varistor voltage with maximum 10 %R

Varistor V / I Characteristic

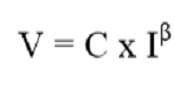

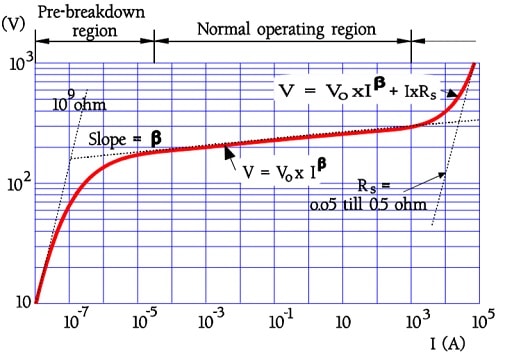

The V/I curve of the elementary varistor in Figure 12. differs slightly from that of the practical varistor that in the normal operation region might be approximated to

where:

C = varistor voltage at 1A.

I = actual working current.

β ≈ 0.03.

A typical V/I characteristic is shown in Figure 16.

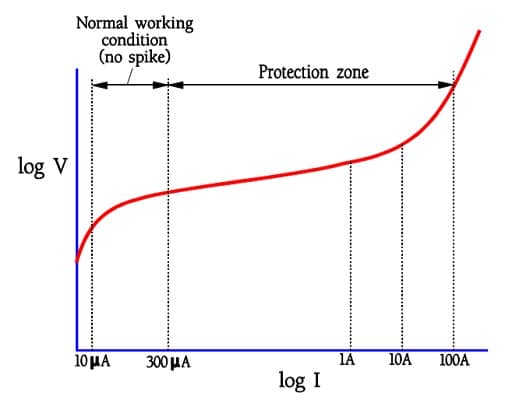

The V/I curve of a varistor has tolerances. When the leakage current is specified one presupposes the highest possible current at a certain voltage. The clamping voltage – the one occurring across the varistor when subjected to transients – is specified as the highest possible at a certain current. Thus the specifications are controlled by the unbroken line in Figure 17. Practical, standard-based limits for the varistor are shown in Figure 18.

Principles of Varistor Voltage Limitation

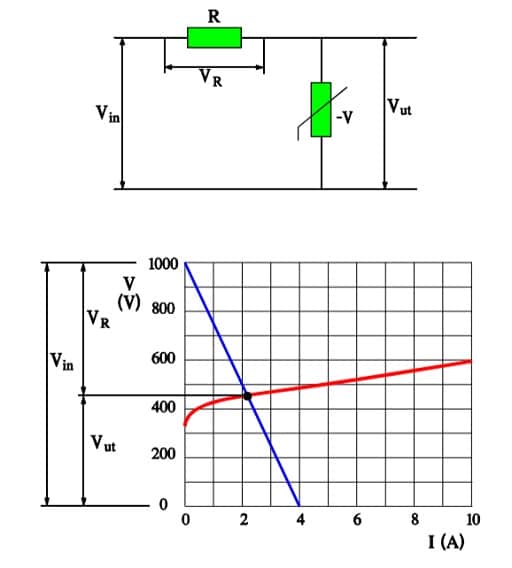

If the varistor is to operate as a voltage limiter a series impedance is required in the circuit. Common straight conductors have both resistance and inductance (≈ 1nH/mm) and provide in themselves a certain protection. Practically, however, the problem is solved by a series resistor of some hundred(s) of ohms (Figure 19.).

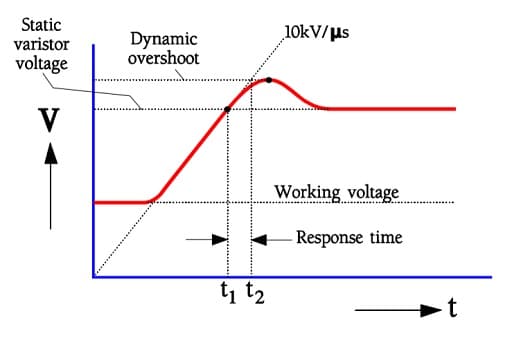

Varistor Response Time

When a varistor is struck by a voltage transient the voltage rises across the component until the cutting characteristics start. There is, however, a short delay, a dynamic effect, that produces a certain overshoot, according to Figure 20. As an example there is shown an incoming pulse with a rise time of 10 kV/µs. The response of the varistor time is specified as the rise time t2 – t1 in the figure. The response time seldom exceeds 20 ns; response time of multilayer varistor SMDs usually is less than 1 ns. The response time sometimes is called turn on time.

Choice of Type

Choosing the correct varistor presupposes a thorough determination of working voltage, including tolerances, expected transients, their duration, pulse energy and repetition frequency. In addition we have to take into consideration environmental requirements and mounting conditions. Connecting two varistors in parallel in order to increase the current load capability should be done only if the varistor voltages (at 1 mA) differ from each other by less than 1 %. Otherwise the unbalance of the load may be considerable and in the most unfortunate cases amounts to 1000:1.

Failure Modes

The most common failure mode is short-circuiting which may occur after unacceptably high and energy rich voltage pulses or after operation at a steady-state voltage beyond the voltage rating. In the latter case the failure mode might change into open-circuit due to melting effects in the terminal joints or rupture of the package when the large amount of energy generated causes expulsion of the package material.

Reliability

The reliability of non-linear resistors, including varistors, is today regarded as relatively good. Not least it depends on serious manufacturers using SPC based production programs and having verified type approvals. Examples of climatic category classified products 40/125/56 are other indications of a good quality. Furthermore, if we choose glass/metal packages the quality will be even better.

Nuclear radiation

Tests with radioactive radiation in the form of neutron, β and γ radiation show that varistors are capable of withstanding high intensities without any effects on the characteristics.

* Occurring capacitance leads to a capacitive shunting that makes the varistor unusable at higher frequencies.

Applications

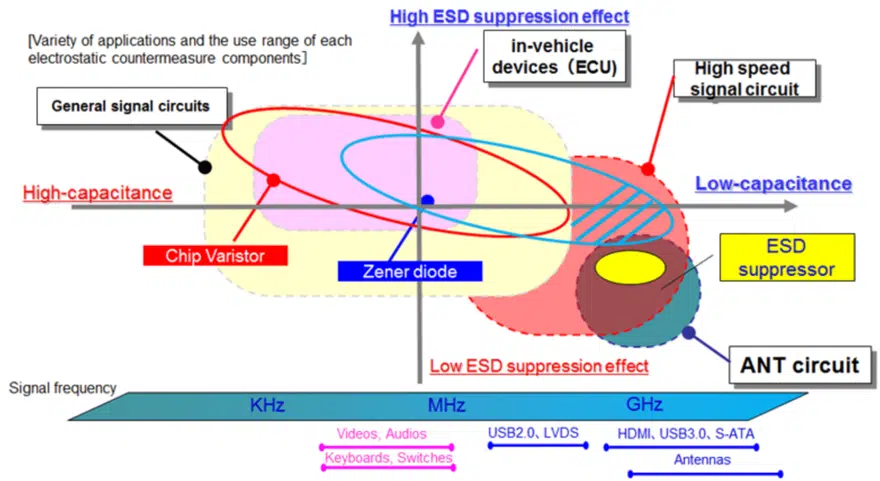

Multilayer SMD varistors are used mostly to protect electronic devices from electrostatic discharge (ESD). See Figures 21. and 22. below

ESD protection benchmarking

Varistor ESD protection applications versus other ESD suppression devices – see Figure 23.

Further reference of varistor applications – see post How to Use Varistors as ESD/Surge Protection Devices

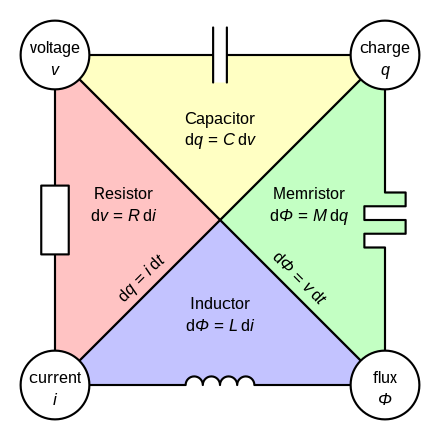

Memristors

Memristors are non-volatile electrically-adjustable resistors. Made mostly from metal oxides, they scale well and are proposed as memory elements in nanometre-scale logic for future brain-like networks.

It was described and named in 1971 by Leon Chua, completing a theoretical quartet of fundamental electrical components which comprises also the resistor, capacitor and inductor. (Figure 25. source: Wikipedia)

Electrical Symbol – see Figure 24.

Memristors have not been yet developed into a mass volume component, nevertheless memristors have gathered a lot of interest by university research as a next generation memory technology by being smaller, more power efficient and yet being able to support more memory states when compared to existing technologies used in our smartphones and computers.

Brain like computing systems using memristors have already been demonstrated.

Detail description is beyond this article scope, for those interested, here are some reference links

- https://passive-components.eu/memristors-key-to-nano-scale-analogue-digital-adaptive-hardware/

- https://passive-components.eu/new-memristor-boosts-accuracy-and-efficiency-for-neural-networks-on-an-atomic-scale/

- https://passive-components.eu/toward-brain-like-computing-new-memristor-better-mimics-synapses/

- https://passive-components.eu/first-programmable-memristor-computer-aims-to-bring-ai-processing-down-from-the-cloud/

- https://passive-components.eu/memristors-supports-brain-like-computing-system/

- https://passive-components.eu/purity-of-materials-may-be-the-key-in-further-memristor-development/

- https://passive-components.eu/nanometers-thin-niobium-oxide-nbo2-memristor-can-bring-breakthrough-in-neuromorphic-ai/

- https://passive-components.eu/graphene-based-memristors-show-promise-for-brain-based-computing/