Samsung Electro-Mechanics develops world’s highest capacitance automotive MLCC ceramic capacitors at 16V rating for ADAS and autonomous driving cars.

Samsung Electro-Mechanics announced on January 19th that it has developed high-voltage, high-capacitance MLCCs for the Advanced Drive Assist System (ADAS), an essential system for autonomous driving cars, and will target the market by expanding its lineup of high-performance automotive products.

Components that control the constant and stable flow of current in the circuits of electronic products, widely used in smartphones, PCs, IT devices, home appliances, automobiles, 5G, and IoT-related products. In particular, automobiles contain at least 3,000 to 10,000 MLCCs for powertrain, safety, driving, infotainment, etc.

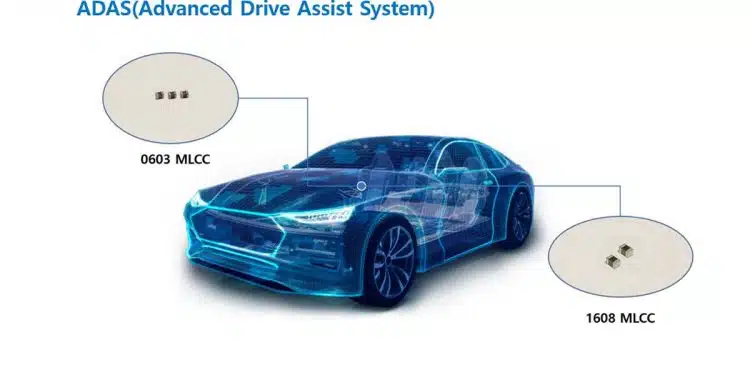

The MLCCs developed this time have high-voltage characteristics rated at 16V (volts) and are available in two models: the 0603 size (0.6mm wide by 0.3mm long) with 100nF (nanofarad) capacitance and the 1608 size (1.6mm wide by 0.8mm long) with 4.7uF (microfarad) capacitance.

These products are used in the Gateway module, a core device for autonomous driving. The automotive Gateway is a core system that provides integrated management of each ADAS function within the vehicle and securely transmits data. Stable power supply and signal noise removal are essential to ensure fast and accurate signal transmission between semiconductors. Especially, due to the advancement of autonomous driving functions, fast charging of electric vehicles, and increased driving distance, ultra-compact, high-capacitance, and high-voltage MLCCs are required.

The two models developed this time offer the industry’s highest capacity and high voltage within the same sizes.

Typically, MLCCs have difficulty satisfying voltage and capacity characteristics at the same time. If the dielectric substances that store electricity are designed to be thicker to increase voltage characteristics, the number of internal dielectric layers that can be stacked decreases, making it difficult to increase capacity. Samsung Electro-Mechanics achieved high capacitance by refining its core raw material, dielectric ceramic powder, to the nanoscale level. In addition, the application of proprietary additives and new methods minimizes the amount of empty space in the dielectric substance, enabling stable operation at high voltages.

Executive Vice President Choi Jeremy, head of the Component Solution Unit at Samsung Electro-Mechanics, said, “The demand for compact, high-performance, and high-reliability MLCCs is increasing significantly due to the electronization of automobiles,” adding, “Samsung Electro-Mechanics will enhance its technological competitiveness by developing and manufacturing core raw materials for MLCCs in-house and strengthen its automotive business by expanding its automotive lineup through internalization of facilities and strengthening production capacity.”

Samsung Electro-Mechanics is strengthening its lineup of high-temperature, high-pressure, and high-reliability automotive products based on its technological prowess in the ultra-compact, ultra-high-capacity MLCC category, and is expanding its supply of MLCCs to global auto component companies and automakers.