This article based on Knowles Precision Devices blog explains what EMI is, why it needs to be filtered and how EMI filters are operating.

to understand what an electromagnetic interference (EMI) filter is, and what it does, we need to first know what EMI is and why it needs to be filtered.

EMI refers to undesirable electromagnetic emissions or disturbances generated either by electronic devices or natural sources in the environment that can interfere with the proper functioning of other nearby devices or systems.

EMI noise can propagate through power supply lines and radiate into the environment, potentially causing disruptions or malfunctions in other electronic systems. For many devices, this could cause big issues, which is why many government organizations have developed regulatory standards for electromagnetic compatibility (EMC), or when two pieces of electronic equipment can function in the same environment without adversely impacting one another.

Further read: Introduction to EMI Filtering

How are EMI Filters Used?

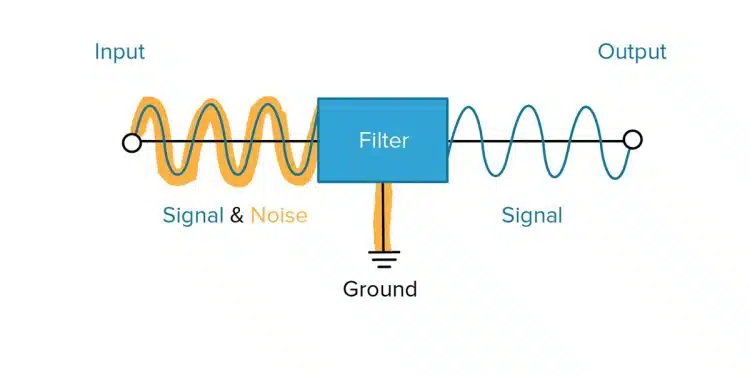

In power electronics, EMI filters are used to suppress and filter out unwanted high-frequency electromagnetic noise generated by the switching operations of power electronic circuits. For ceramic EMI filters specifically, the main function of these components is to provide a low-impedance path to the unwanted high-frequency noise while allowing the desired power signals to pass through with minimum impedance. The EMI filter acts as a low-pass filter, attenuating the high-frequency noise and preventing its propagation (featured image).

What Applications Need EMI Filters?

EMI filters help ensure reliable operation of power electronic systems by effectively reducing EMI noise and preventing interference with sensitive electronic components which minimizes the risk of malfunction or data corruption, and helps manufacturers meet electromagnetic compatibility standards. EMI filters are commonly used in applications such as power supplies, inverters, motor drives, LED lighting, and other electronic devices where EMI mitigation is critical. With proper EMI filtering, these devices can then be trusted for use in mission-critical applications where failure is not an option such as medical devices and aerospace and defense equipment.

Why are Ceramic Capacitors a Good Fit for EMI Filters?

Ceramic materials possess excellent electrical and mechanical properties that make them suitable for EMI filter applications. Ceramic EMI filters are typically constructed using multilayer ceramic capacitors (MLCCs) or ceramic disc capacitors. These capacitors are designed to have high capacitance values and low equivalent series inductance (ESL) and equivalent series resistance (ESR) to minimize the impedance of the desired power signals. EMI filters made with ceramic are also designed to exhibit high impedance at high frequencies, effectively filtering out the EMI noise.

When ceramic capacitors are used for EMI filters, the filters are typically connected in parallel with the power supply lines or between the power supply and the electronic device being protected. The MLCC used as a filter can be integrated into the printed circuit board (PCB) design or implemented as discrete components. The number and configuration of the filters will depend on the specific EMI requirements and the complexity of the power electronics system.

Helping You Select the Ideal EMI Filtering Option

When an electronic system needs a capacitor to serve a critical role, such as EMI filtering, it is best to consult with expert engineers that can work with you to properly specify the size and type of capacitor needed. As a specialty components manufacturer with unrivaled ceramics expertise, Knowles Precision Devices can help. We make a variety of high-reliability surface and panel mount filters, discoidal capacitors, and planar capacitor arrays that can be used for EMI filtering. Our core wet manufacturing process and ceramic handling expertise allows us to produce components with mechanical precision and electrical accuracy, enabling filter assemblies to function reliably and withstand the most rigorous of electrical specifications.