Würth Elektronik has extended its WE‑LT conductive textile gasket family with a new halogen‑free variant aimed at enclosure and display designers who need reliable EMI shielding and environmental sealing.

The self‑adhesive gaskets combine high shielding effectiveness, IP54 protection, and UL 94 V‑0 flammability performance while meeting current EU ecodesign and RoHS requirements.

Key features and benefits

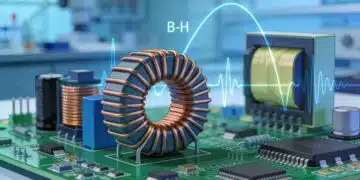

The halogen‑free Würth Elektronik WE‑LT conductive textile gaskets target electromagnetic compatibility (EMC) issues around housing seams, doors, covers, and panel interfaces where low impedance contact and mechanical sealing are both needed.

Key electrical and regulatory characteristics include:

- Shielding attenuation of more than 80 dB at 100 MHz, suitable for reducing radiated and conducted emissions in typical industrial and information technology equipment.

- Typical surface resistance below 0.08 Ω, supporting low impedance bonding between mating metal surfaces.

- Halogen‑free construction compliant with EU Ecodesign 2009/125/EC requirements for displays and similar equipment.

- RoHS‑compliant material selection for use in regulated markets.

- UL 94 V‑0 flammability rating, helping system designers meet safety and fire protection standards in end equipment.

From a mechanical and environmental perspective, the gaskets are designed to simplify integration into existing housings:

- Self‑adhesive (pressure‑sensitive adhesive, PSA) backing for easy placement on metal flanges and frames without additional mounting hardware.

- IP54 protection against dust and splashed water, allowing use in light industrial environments, control cabinets, and operator panels.

- Broad selection of standard profile shapes (square, D, C, P, L, M, and blade) for different mounting geometries, door edges, and bezel designs.

- Option for custom shapes and cut‑to‑length formats, enabling tailored solutions for complex housings or large display frames, with no specified additional tooling costs according to the manufacturer.

For purchasing and project engineers, the combination of halogen‑free material, established regulatory compliance, and a standard profile portfolio reduces qualification effort compared to custom in‑house gasket solutions.

Typical applications

Würth Elektronik positions the halogen‑free WE‑LT EMC gaskets for use wherever two conductive parts of an enclosure must be electrically bonded after assembly and simultaneously sealed against dust and splashed water.

Typical application areas include:

- Display assemblies and monitor housings, especially within the EU where halogenated flame retardants in housings and stands for electronic displays are restricted.

- Metal housings for industrial controllers, power supplies, and communication equipment that require EMI shielding along removable covers or door seams.

- Control cabinets and rack systems where front doors, side panels, or cable entries need both EMC shielding and environmental sealing.

- Input/output connection panels, interface plates, and backplanes where connectors penetrate shielded housings.

- Grounding connections between housing parts or between doors and frames to ensure low‑impedance RF bonding.

In practice, these gaskets help maintain the shielding effectiveness of conductive housings at all openings, hinge lines, or access points where direct metal‑to‑metal contact is difficult to guarantee over the product lifetime.

Technical highlights

Construction and materials

The WE‑LT halogen‑free conductive textile gaskets are built as a composite structure:

- Conductive textile: Woven polyester fabric with nickel‑plated copper threads to provide conductivity, corrosion protection, and abrasion resistance.

- Optional aluminum layer versions: Certain variants also include an aluminum layer for specific shielding performance or mechanical requirements according to the manufacturer’s documentation.

- Elastic core: Urethane foam in various densities between 45 kg/m³ and 150 kg/m³, allowing the gasket to deform under compression, tolerate tolerances, and recover after opening/closing cycles.

- Pressure‑sensitive adhesive (PSA): A self‑adhesive backing to fix the gasket to one side of the housing or frame before final assembly.

The nickel plating on the copper threads is intended to protect against corrosion in the presence of humidity and to limit wear from repeated opening and closing of doors or covers.

Mechanical behavior and compression

The gasket performance depends strongly on proper compression during installation:

- A recommended compression ratio of approximately 30% of the original gasket height is specified for normal operation.

- At this compression level, contact area and pressure are sufficient to maintain low surface resistance and stable shielding performance, while preserving foam elasticity and service life.

- The range of foam densities enables designers to choose a softer profile for light door closures or a stiffer one where high closure forces or larger gaps must be bridged.

For design engineers, this means that the correct profile height and foam hardness should be selected based on expected tolerances, door forces, and the number of opening cycles over equipment lifetime.

Profiles and geometries

Standard profile shapes offered for the WE‑LT halogen‑free series are:

- Square profiles for flat flange‑to‑flange sealing and straightforward groove mounting.

- D profiles for door seals and edge mounting where one side must compress against a flat surface.

- C and P profiles for clipping around thin metal edges or bezel frames.

- L and M profiles to adapt to corner geometries or step‑like housing interfaces.

- Blade profiles for tight spaces, narrow edges, or where minimal width is available for an EMC seal.

Custom profiles and cut‑to‑size parts are also available, supporting tailored gaskets for display cutouts, instrument panels, and non‑rectangular covers.

Design‑in notes for engineers

To get reliable EMC and environmental performance from the WE‑LT halogen‑free gaskets, a few practical design‑in aspects should be considered.

EMC and grounding considerations

- Ensure that both mating surfaces are conductive and free from insulating coatings at the contact area, or use defined contact windows through paint layers.

- Maintain a continuous gasket path along the entire seam whenever possible; avoid gaps or sharp discontinuities that could compromise shielding.

- Consider the frequency range of concern: shielding attenuation above 80 dB at 100 MHz is strong for many industrial and communication applications, but high‑frequency behavior and specific test conditions should be verified in the datasheet.

- Use the gaskets as part of a system‑level EMC concept including filter components, cable shielding, and PCB layout measures rather than as a stand‑alone fix.

Mechanical integration and assembly

- Design flanges and door frames so that the gasket is compressed to roughly 30% of its original height in the final assembled state, within the tolerance range of mechanical parts.

- Avoid over‑compression, which can cause permanent deformation, higher closure forces, and reduced lifetime.

- Take advantage of the self‑adhesive backing for easy assembly, but ensure clean, degreased surfaces for reliable adhesion over time.

- For doors or covers that are opened frequently, select foam density and profile shape that balance ease of closing with long‑term mechanical durability.

Environmental and regulatory aspects

- The halogen‑free formulation and compliance with EU Ecodesign 2009/125/EC make the WE‑LT halogen‑free gaskets particularly suitable for display housings and stands placed on the EU market.

- UL 94 V‑0 flammability performance supports their use in safety‑critical equipment where flame retardancy is mandatory.

- RoHS compliance simplifies global sourcing and helps avoid future requalification due to material restrictions.

By integrating these gaskets early in the mechanical and EMC design, engineers can reduce the risk of late‑stage EMC test failures and mechanical rework on enclosure designs.

Source

The information in this article is based on the official Würth Elektronik press release about the WE‑LT halogen‑free conductive textile gaskets and associated manufacturer documentation.