Vladimir Azbel, Independent consultant on tantalum capacitors presents a computational module that significantly accelerates the development of new tantalum capacitor designs and the reduction of experimental cycles.

The module provides experienced specialists fast multi-parameter optimization, microstructure prediction in digital form. Engineers with limited practical background, the system defines parameter ranges, highlights dominant factors influencing Δ, and guides the user toward safe and optimal regimes.

As a result, the module serves as a unified engineering tool that transforms anode design from empirical selection to predictive optimization, improving development efficiency and reliability of the final product.

Abstract

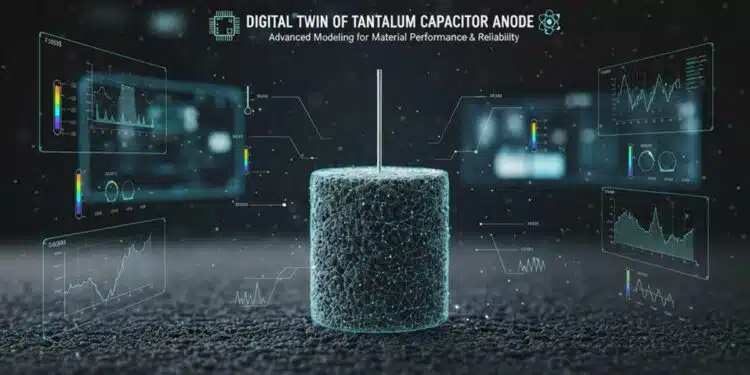

This work presents an industrial-grade algorithm-driven digital twin of a tantalum capacitor anode spanning the entire technological chain—from powder characteristics and sintered pellet microstructure to electrolyte conductivity and formation conditions.

The developed mathematical model integrates thermophysical, electrical, and structural relationships into a unified computational system, enabling the prediction of thermal risk, the optimization of formation parameters, and the minimization of defect probability during Ta₂O₅ growth.

A computational relationship is introduced linking the formation voltage to two technological factors:

- the neck size determined by sintering and powder properties

- the electrolyte conductivity, which defines the ionic-transport resistance during formation.

It is shown that electrolyte conductivity, together with the formation current, governs oxide-growth rate and directly influences defect probability. The embedded algorithm engine identifies dominant factors affecting thermal behavior and generates recommendations for optimal processing conditions. The proposed algorithm-based digital twin enables predictive process control, digital recipe generation, and improved reliability of tantalum capacitors in mass production.

1. Introduction

The electrical formation of tantalum capacitor anodes is governed by a complex interplay of powder properties, sintered-pellet microstructure, electrolyte composition, and formation parameters. Small deviations in any of these factors can lead to local overheating, oxide defects, and increased leakage current, ultimately reducing capacitor reliability. Traditional development approaches rely on empirical adjustments and multiple experimental iterations, which provide limited predictive capability and significantly increase development cost. To overcome these limitations, we introduce an industrial digital algorithm-twin integrating physical models, production data, and algorithmic tools across all stages of the technological chain: powder characterization, microstructure reconstruction, electrolyte modeling, and formation-process simulation. The system quantitatively links structural and electrochemical properties to the anode’s thermal behavior, predicts thermal risk through the heat-removal coefficient Δ, and identifies optimal formation conditions. The digital twin replaces empirical tuning with predictive optimization, reducing development time and variation in product quality.

2. Algorithm Module for Overheating Analysis and Formation Optimization

The developed module is a specialized industrial algorithm component designed to evaluate and minimize thermal risk during electrical formation.

Key capabilities

- Identification of dominant factors

- The system automatically determines the most influential variables among dozens of technological parameters.

- Prediction of thermal risk and dielectric defects

- Using the Δ metric, the module estimates the likelihood of overheating and defect formation in the Ta₂O₅ layer.

- Digital microstructure reconstruction

- The model reconstructs functional microstructural characteristics, including SSA, pore/neck-size distribution, and effective thermal conductivity.

- Optimization of formation conditions

- The algorithm determines the safe formation current Ir, allowable electrolyte conductivity σ, and optimal formation voltage FV for a given neck size.

- Reduction of experimental cycles

- Application of the digital twin reduces required production trials by 60–80%.

Target Function and Optimization Parameters

Within the algorithm module, the computational program implements a target optimization function whose purpose is to ensure safe thermal behavior of the anode during formation and to optimize the technological recipe.

The algorithm evaluates and optimizes the following technological parameters of anode production:

- primary powder particle size

- sintering temperature

- sintering time

- pressing density

- electrolyte conductivity σ and its temperature

- formation current

- formation voltage FV

The program computes the parameter Δ, which acts as a digital indicator of overheating risk during formation. A higher Δ corresponds to greater thermal stability and lower defect probability.

The target function guiding the optimization is: max Δ = f(powder, microstructure, σ, T, If, FV)

Thus, the algorithm seeks a combination of microstructural parameters, electrolyte characteristics, and formation conditions that maximize Δ while maintaining manufacturability and reliability.

3. Mathematical Model of Thermal Risk (Δ)

The thermal-risk indicator Δ describes the anode’s resistance to local temperature rise and is defined as:

Δ = Qout / Qgen

Interpretation:

- Δ < 10 — High overheating probability

- 10–18 — Borderline regime

- >18 — Safe formation

4. Relationship Between Electrolyte Conductivity and Formation Voltage

FV(σ)=A·(1/σ) + B.

For the dataset used:

FV(σ)=1.18×10^5σ + 23.2

5. System Architecture and Computational Workflow

Subsystems:

- Microstructural-modeling block

- Electrochemical block

- Thermal block

- Optimization block

- Algorithm-based factor-analysis module

6. Conclusion

The developed module represents a complete industrial digital twin of a tantalum capacitor anode, integrating powder science, microstructure modeling, electrochemistry, and thermal analysis within a unified computational framework. Incorporation of the conductivity–voltage relationship enables early determination of formation conditions, reduces overheating probability, and increases Ta₂O₅ reliability. The system provides a practical tool for design, monitoring, and optimization of technological processes in tantalum-anode manufacturing.

The developed computational module can be fully integrated with the AI component of the digital twin. AI algorithms automatically identify the most influential technological parameters, predict variations of the thermal coefficient Δ, and enable closed-loop optimization of formation conditions. When the required design specifications of the tantalum capacitor — nominal capacitance, rated voltage, and case code — are provided, the AI-integrated system can automatically generate a complete technological recipe for the anode, including powder parameters, pressing conditions, sintering profile, electrolyte conductivity, and formation regime. This approach ensures high process reproducibility, reduces the number of experimental iterations, and improves anode reliability through predictive control of thermal and electrochemical characteristics.