Vladimir Azbel Ph.D., semiconductor process reliability engineer consultant, Israel proposes an innovative solution for tantalum capacitor production quality enhancement: introducing an internal standard for incoming inspection to assess the quality of the supplied powder.

The production of tantalum capacitors is a complex and labor-intensive process, consisting of a row of manufacturing, control, and auxiliary operations. The proposed innovative method, in addition to existing quality control methods, will ensure the stability reliability, and performance of tantalum capacitors.

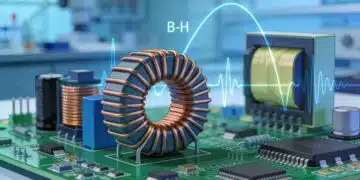

The initial operations in the production of tantalum capacitors include sintering tantalum powder, obtaining a sintered volumetric-porous pellet, and its formation, with the created anode, where the main electrical characteristics of the future capacitor, such as capacitance, dissipation factor, and leakage current, are formed.

The quality of the obtained anode is controlled by two operations: inspection of the appearance of the sintered pellet and, after formation, checking the current electrical characteristics of the anodes. The electrical characteristics of the anode depend on many factors, beginning from the morphology of the porous structure of the sintered pellet, which must satisfy parameters formation, set by the manufacturer and allow minimizing the risk of internal stress formation. Thermal annealing operations are used to reduce the level of internal stresses in the anodes; however, currently, there is no control over the degree of stress reduction and the residual stress level in the anode material.

During storage and especially the exploitation of tantalum capacitors, due to the relaxation of residual internal stresses, lead to deterioration of their electrical parameters, primarily an increase in leakage current.

Created of internal stresses in sintered pellets is a well-known problem in powder metallurgy. Usually, for control of internal stresses, mechanical testing is most often used, including recording the Stress-Strain curve and determining its parameters such as the modulus of elasticity and yield strength. These data can be used as indicators for the estimate of residual stresses in the sintered pellet and the anode.

Since aging and degradation of electrical properties significantly affect the quality of tantalum capacitors, there is a need to control the influence of residual internal stresses in volumetric-porous tantalum anodes. It is proposed to introduce an additional control operation into the list of operations in anode

production, which consists of measuring the mechanical properties of the anodes.

Control of mechanical properties does not require additional equipment, as it can be performed on standard testing machines used in the measurement laboratories of enterprises, that issue tantalum capacitors. There is no need for special samples to measure mechanical properties, as a limited number of

sintered pellets, or anodes (from 3 to 10) can be used. The procedure for measuring and processing the deformation diagram to obtain values of mechanical properties is simple and can be carried out by a midlevel specialist or using existing software.

Determining the mechanical properties of anodes at various stages of their production can provide useful information for adjusting technological processes. This data can include information about the morphology of the porous structure of the sintered pellet and its impact on the quality of the initial tantalum

powders, etc.

In addition, mechanical properties data can be used: for monitoring the stability of technological processes, and the quality of anodes made from different batches, lots, powders, etc.

Measuring the mechanical properties of sintered pellets and comparing them with reference characteristics allows for evaluating the resistance of the anode material to mechanical and thermal loads.

Measuring the mechanical properties after formation and thermal annealing of the anode provides direct information about residual stresses in the anode material, which can be used as an express indicator of the capacitor’s quality.

Comparing the measurement results with the benchmark allows for determining which of the electrical parameters anode needs improvement and optimizing the technological modes on which it depends, ultimately improving the quality of the final product.

Benchmark characteristics of the mechanical properties of sintered pellets and anodes can be used in sintered pellets and anodes, from capacitors, that have passed long-term tests or got by striping from capacitors that have successfully passed operation. The proposed mechanical characteristics include the

modulus of elasticity, yield strength, and strain hardening coefficient, which reflect porosity, neck size, and defectiveness, and are responsible for capacitance, forming voltage, and anode leakage currents.

Introducing control over the mechanical properties of the sintered pellet and anode will improve the quality and operational durability of tantalum capacitors, an additional competitive advantage of the manufactured products.

In Summary

“Introducing an Innovative Internal Standard for Powder Quality Assessment in Tantalum Capacitor Production”

I propose an innovative solution: introducing an internal standard for incoming inspection to assess the quality of the supplied powder. This standard, specially developed for this purpose, is based on the mechanical properties of sintered pellets. Producing high-quality powder is a multifaceted technological challenge. Factors such as raw material purity, processing methods, chemical composition, particle size, and distribution play a crucial role. Each of these parameters has a specific range adapted to specific requirements.

Tantalum powders used in capacitors and supplied by various manufacturers undergo purity checks according to ASTM requirements and consumer certification standards, under which incoming inspection is conducted. However, differences in their production processes can lead to internal variations that may affect the reliability of capacitors made from these powders. Deviations within the limits set by certificates and the production process can influence both mechanical and electrical characteristics. Maximum allowable changes have been established for the latter. The certification process should guarantee optimal electrical characteristics of the anode.

Despite the experimental data provided by certificates and experimental data on the electrical characteristics of various batches of powder falling within acceptable limits, this did not guarantee acceptable leakage currents in all tested batches. This is because the electrical characteristics of the anode are not directly related to the morphology of the porous structure of the sintered pellet (the parameters of formation are defined by the customer). To maintain the values of electrical characteristics in different batches, it is necessary to ensure the identity of the morphology of the porous structure of the sintered pellet in the tested batches. This can be controlled through the mechanical properties of the sintered pellet.

Implementing an internal standard for incoming inspection based on mechanical properties will help reduce the time and financial costs of using a powder that does not meet the requirements for producing tantalum capacitors. While the analysis of chemical composition and other powder parameters can be addressed in existing certification, the mechanical properties of sintered pellets can serve as an additional quality indicator, aiding in ensuring the stability of capacitor electrical characteristics.