Many power electronics today are being designed for use in high-temperature, high-voltage environments, such as inside electric vehicles (EVs). However, size, weight, and power (SWaP) are also key factors driving electronic product development.

These conflicting design criteria are an issue for many electrical engineers because space is not available to simply add a cooling system, as this will add weight and increase the product’s overall footprint. Therefore, many of these electronic components are susceptible to “running hot” at the high temperatures and high voltages used in these tiny spaces.

At Knowles Precision Devices, we thought we could balance these two conflicting demands through dielectric material innovation. And we were right. With our newest line of multilayer ceramic capacitors (MLCCs) built with Hiteca™, we can deliver high capacitance stability over high temperature and voltage as well as lower parasitic losses under common operating conditions.

More specifically, Hiteca™ is a low loss, semi-stable Class II dielectric that features improved capacitance stability, low equivalent series resistance (ESR) and equivalent series inductance (ESL), 0 percent aging rate with no loss of capacitance over time, and a typical capacitance reduction of <45 percent at full rated voltage. Additionally, with lower self-heating properties and low loss operation, these capacitors can handle higher ripple currents than conventional ceramic capacitors. This unique combination of qualities makes Hiteca™ MLCCs the perfect choice for applications such as DC bus smoothing, while their non-piezo construction makes them ideal for use as snubber capacitors.

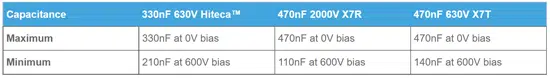

The table below shows the maximum and minimum capacitance values measured, and the bias voltage at which those values were obtained. As you can see, Hiteca™ provides the highest capacitance at 600Vdc applied bias, despite having the lowest capacitance rating.

With our new line of Hiteca™ MLCCs we can help customers optimize their power electronics, as these high-capacitance MLCCs are designed to operate reliably and efficiently, even in the most demanding applications.