This guideline summarizes “other resistor rechnologies”: metal element, metal oxide / metal glaze, carbon film / carbon composition, conductive plastic, and metal foil precision resistors with a focus on construction, power handling, stability, noise, surge/pulse capability, and typical applications.

Key Takeaways

- This guideline covers various “other” resistor technologies, including metal element, metal oxide/glaze, carbon film, carbon composition, conductive plastic, and metal foil resistors.

- Key characteristics include construction methods, power handling capabilities, stability, and typical applications for each resistor type.

- Metal element resistors excel in high power density and surge tolerance, while metal oxide/glaze resistors offer good environmental resilience and high voltage performance.

- Carbon film resistors are suitable for cost-sensitive designs, and carbon composition resistors are often used in legacy applications.

- Metal foil precision resistors provide ultra-low TCR and noise, ideal for high-accuracy systems and precision measurements.

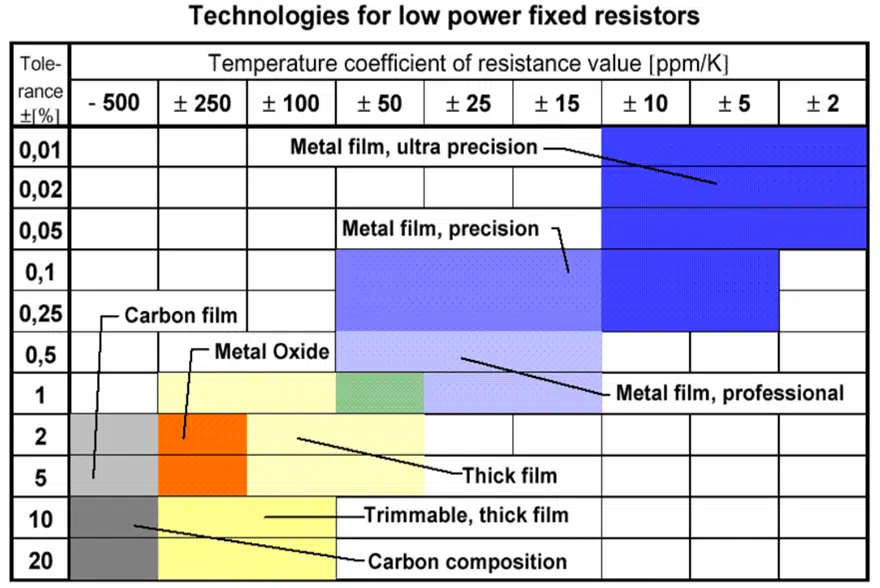

The following Table 1. compares TCR vs tolerance for resistor technologies comparing its key characteristics

Metal Element Resistors

Construction and Variants

Metal element resistors use a bulk metal conductor rather than a thin resistive film.

Common constructions are:

- Flat metal strip (CuMn, NiCr, FeCrAl or similar) welded to copper terminations and encapsulated in epoxy or molded package.

- Metal alloy plate or extended lead frame etched or punched to form a low‑ohmic pattern, then overmolded or mounted on an insulated substrate.

- Metal element on ceramic or metal‑clad substrate for chassis‑mount power resistors.

These constructions minimize resistive path length and maximize cross‑section to achieve very low resistance with high power dissipation.

Key Characteristics

- Resistance range: Typically from below 1 mΩ up to a few Ω for current sense and power shunts.

- Power capability: From sub‑watt SMD shunts up to hundreds of watts in chassis‑mount packages, often limited by package thermal resistance rather than element material.

- Stability: Very good long‑term drift compared with film technologies; the resistive element is bulk metal with limited structural or chemical change in operation.

- TCR: Low to moderate (typical ranges from roughly 20 to 200 ppm/°C depending on alloy and value), optimized in precision current sense types.

- Frequency behavior: Construction is inherently inductive when the current path forms a loop or spiral; advanced low‑inductance patterns (e.g. Kelvin shunts, four‑terminal designs) mitigate this but do not fully eliminate inductance in many power types.

Advantages

- Very high power density, especially at low resistance.

- Excellent overload tolerance for steady‑state and longer‑duration surges compared with thin film.

- Good long‑term stability and relatively low noise (metal conduction, no grain‑boundary hopping mechanism typical of carbon).

Limitations

- Inductance can degrade performance in fast switching or RF current sense applications; layout and pattern design become critical.

- Resistance range is limited; not suitable for high‑ohmic signal levels where film or metal foil are preferred.

Typical Uses

- Power resistors (braking, load, pre‑charge) where low value and high power are required.

- Current sense in SMPS, automotive, battery management, and motor drives, often using Kelvin connections for accurate measurement.

- Braking and snubber networks where energy must be dissipated reliably and repeatedly.

- Surge / inrush limiting where robust metal elements can survive repeated overloads within defined derating.

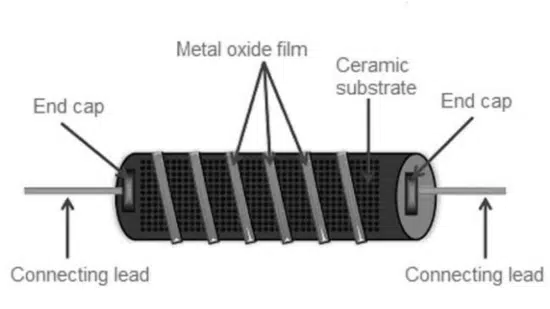

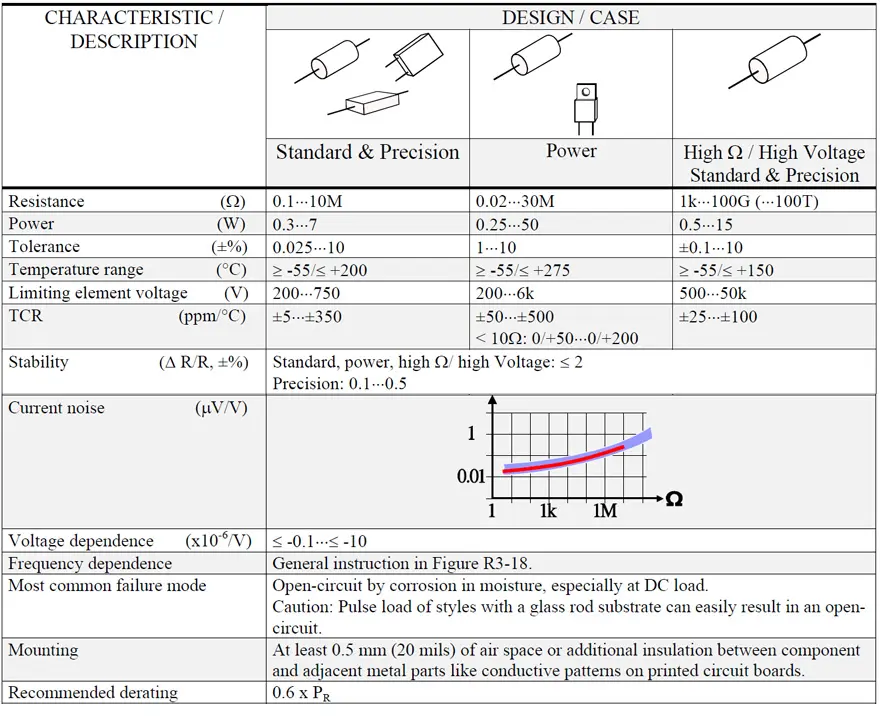

Metal Oxide (METOX) and Metal Glaze Resistors

Construction

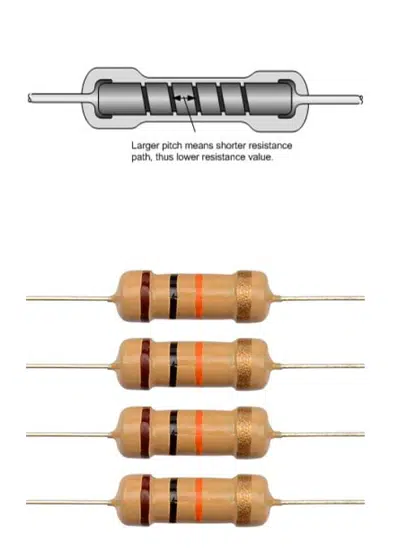

Metal oxide and metal glaze resistors are ceramic‑rod resistors with an inorganic resistive film:

- A ceramic rod (or glass tube) is coated with a metal oxide such as stannic oxide, obtained by reacting the hot substrate with stannic chloride vapor.

- Alternatively, a metal film is first deposited and then oxidized in oxygen to form a stable metal oxide layer.

- The resistive film is usually spiral‑cut to set the resistance; inductance‑limiting serpentine spiral patterns can reduce parasitic inductance.

- Terminations are formed by metal end‑caps or leads, followed by protective coating or molded encapsulation.

Metal glaze resistors use conductive metal or metal‑oxide particles dispersed in a glass matrix fired on a ceramic substrate, creating a granular, glaze‑type resistive layer.

Electrical Characteristics

- Resistance range: From low ohmic values into high‑ohmic and high‑voltage ranges, including values above 100 GΩ for specialized designs.

- TCR: Typically moderate (on the order of ±200…±1000 ppm/°C depending on film composition and value); precision grades are available but not at the level of metal film or foil.

- Noise: Very good for metal oxide, second only to metal film among the film‑type resistors.

- Voltage capability: Excellent high‑voltage performance thanks to thick ceramic bodies, long creepage paths, and robust inorganic films.

Surge and Environmental Performance

- Surge capability: Metal oxide and metal glaze resistors tolerate substantial overload in power terms and are widely used where energy pulses or surge events are expected.

- Thermal robustness: Because the film is already an oxide, there is no further oxidation; certain power types allow hot‑spot temperatures up to about 275 °C, subject to data‑sheet confirmation.

- Environmental resistance: Integrated films on glass or ceramic exhibit good resistance to humidity and contamination, particularly in hermetic or glass‑coated designs.

Advantages

- Good balance of surge endurance, power capability, and environmental robustness.

- Low noise relative to carbon technologies.

- Suitable for high‑voltage dividers and high‑ohmic applications where leakage and surface tracking must be controlled.

Limitations

- Less precise and less stable than high‑quality metal film or metal foil for precision signal applications.

- Some types can be sensitive to very short, high‑amplitude power pulses despite good overload ratings in longer time windows, requiring careful pulse‑load evaluation.

Typical Uses

- High‑voltage resistors in power supplies, CRT and X‑ray equipment, and HV dividers.

- Surge‑resistant dropper and bleeder resistors in mains circuits and SMPS.

- Snubber and damping networks where combination of voltage withstand and energy handling is critical.

- Replacement for carbon composition in many legacy designs requiring improved safety and stability.

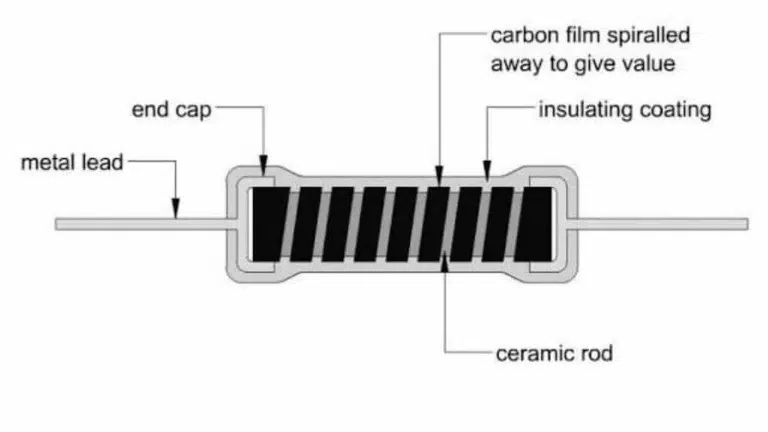

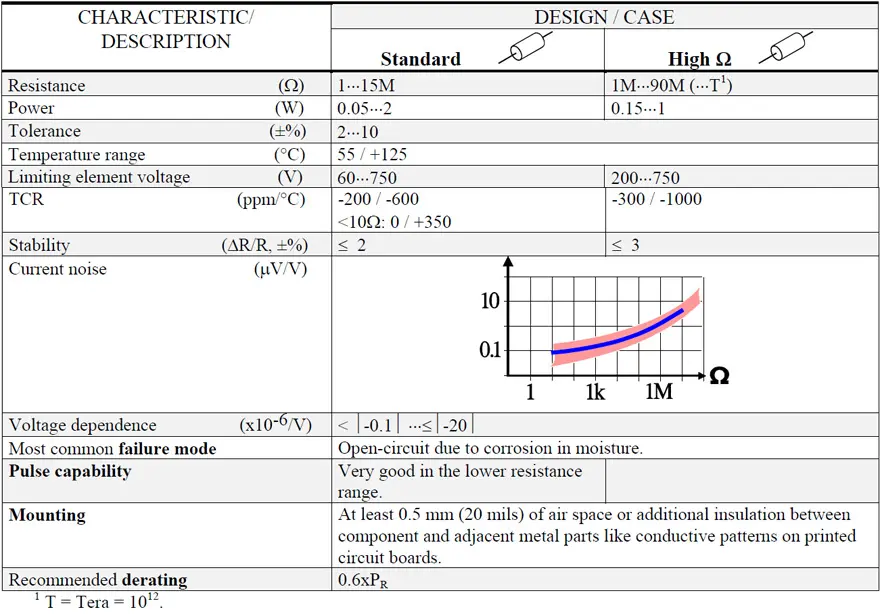

Carbon Film Resistors

Construction

- A ceramic rod is coated with crystalline carbon, either by vacuum deposition or by cracking hydrocarbons onto a hot substrate at temperatures approaching 1000 °C.

- The film thickness typically ranges from about 0.04 to 40 μm, thicker films corresponding to lower resistance values.

- The film is usually spiral‑cut to adjust resistance; end‑caps and lead wires complete the through‑hole component.

Electrical Characteristics

- Resistance range: Broad, extending from low ohmic values up to very high resistances; below roughly 10 Ω, many manufacturers switch to metal film technology while keeping the same external look.

- TCR: Strongly negative, typically between approximately –250 and –1000 ppm/°C depending on resistance value.

- Stability: Good for “stable” grades where long‑term drift can remain within about 1%; cheaper parts may drift more.

- Noise: Higher than metal oxide and metal film, and increasing with resistance value; low‑ohmic parts can approach metal oxide noise levels.

Pulse and Surge Capability

- Low‑ohmic, thick‑film carbon resistors exhibit excellent pulse capability, especially when the film is not spiraled because current distribution is more uniform.

- Non‑spiraled, molded or film‑on‑rod constructions are used specifically for pulse and surge applications where temperature rise is localized but short.

When Carbon Film is Still Relevant

- Cost‑sensitive designs using 5% E24 series where tight tolerance and ultra‑low noise are not required.

- Circuits needing good pulse load capability at moderate cost (meter protection, simple crowbar circuits, ignition or discharge paths).

- High‑ohmic, hermetic glass‑sealed carbon film resistors where values up to the TΩ range are required with reasonable stability and extremely low leakage; care must be taken to avoid contamination from handling.

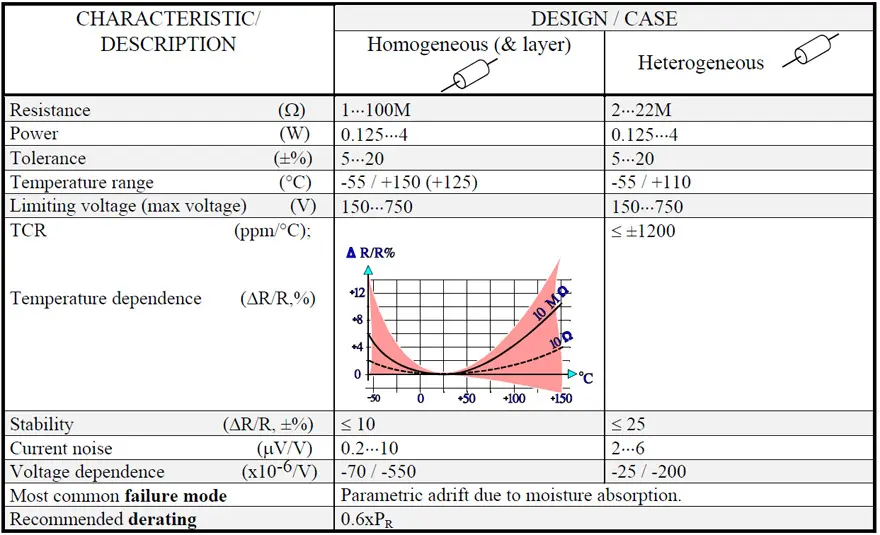

Carbon Composition Resistors

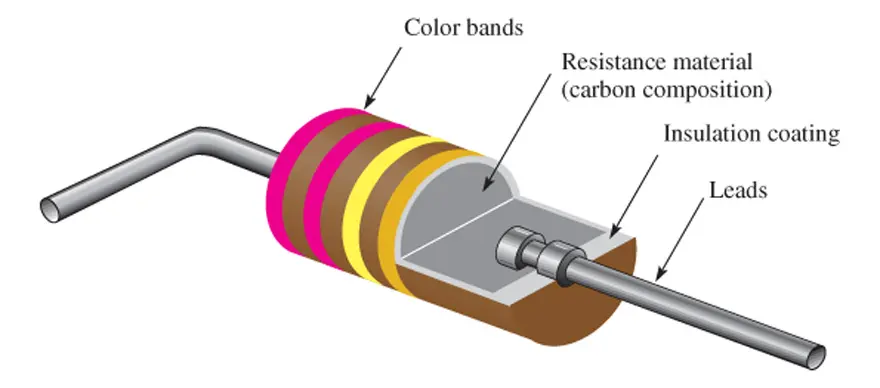

Construction

Carbon composition resistors are bulk resistors where the current flows through a carbon‑based composite body rather than a film.

- Homogeneous types: Carbon powder, binder, and resin are mixed and molded to form a solid resistive cylinder.

- Heterogeneous types: Carbon powder is mixed with a filler such as silica or aluminum oxide before molding, which generally worsens stability but can reduce cost.

- Layer types: A dispersion of graphite and binder is applied to a glass tube and dried, resulting in characteristics similar to homogeneous types but higher mechanical vulnerability.

The homogeneous molded design is qualitatively best and historically used in high‑reliability and safety‑critical circuits.

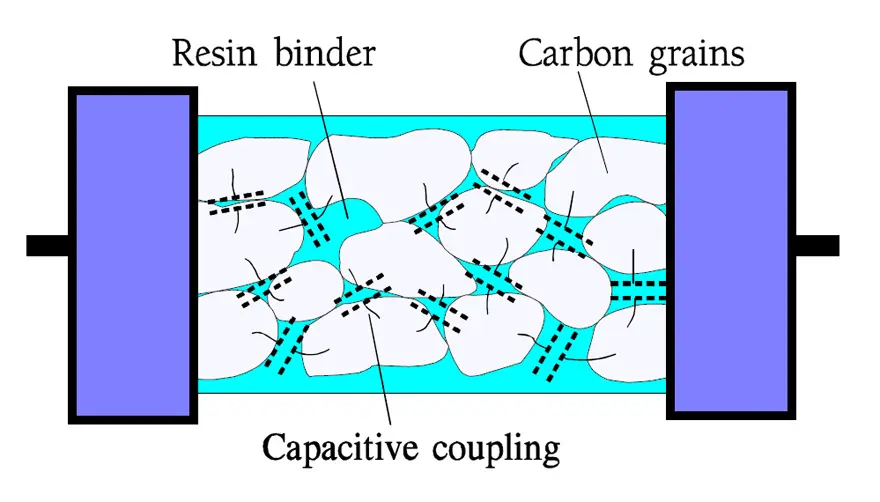

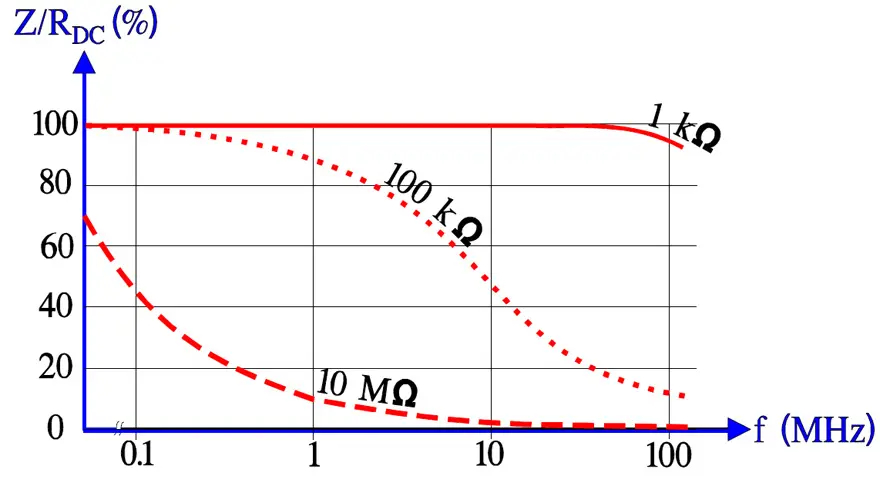

Electrical and Frequency Behavior

- The resistive body contains conductive granules separated by insulating material, with capacitive coupling between granules.

- At higher frequencies, this network produces significant capacitive shunting, reducing impedance compared with DC resistance.

- Because current is divided over a very large number of parallel paths, the effective inductance is extremely low despite the bulk geometry.

Pulse and Failure Behavior

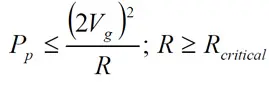

If the capacitive frequency dependence is great the inductance is the smaller. The current passes through an infinite number of branches connected in parallel which altogether creates a negligible inductance inside the resistor body. This, however, doesn’t mean that we have found the ideal component for pulse loads even if we occasionally may see such assertions. Only low resistance values, where the resistor body consists mainly of pure carbon, may correspond to such assertions. Otherwise strong surge currents might damage the uncountable contact spots in the current paths. The pulse power Pp should be limited to

- The low inductance has often been interpreted as ideal for pulse applications; however, strong surge currents can damage numerous internal contact points, leading to drift or failure.

- Only low‑resistance bodies that are mostly pure carbon approach the “ideal pulse resistor” behavior; most values require limited pulse power to avoid damage.

- Importantly, homogeneous carbon composition resistors tend to fail gradually (drifting resistance, sometimes low‑ohmic or open) rather than by explosive open‑circuit fracture, which was valued in safety‑critical circuits.

- Parts from low‑quality sources can present a genuine fire risk under severe overload.

Other Characteristics

- TCR: Strongly non‑linear with temperature; values vary significantly over operating range.

- Noise: High current noise compared with films due to granular conduction mechanism.

- Stability: Poor long‑term stability; attempts to correct low resistance by baking or conditioning yield only temporary improvement.

When Carbon Composition is Still Relevant

- Legacy equipment where original behavior (including noise, pulse response, and failure mode) must be preserved for authenticity or qualification reasons.

- Safety‑critical applications in older designs where the homogeneous molded body and non‑catastrophic failure mode were explicitly specified.

- Special pulse circuits that were originally designed around particular carbon composition behavior, provided pulse energy is carefully limited.

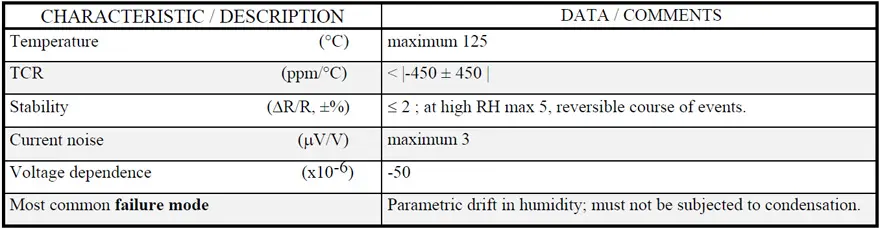

Conductive Plastic Resistors

Construction and Position in the Family

Conductive plastic is closely related to carbon composition but is mainly used as a potentiometer track material rather than fixed resistors.

- Carbon powder and thermosetting plastic plus binder are mixed and molded or formed as a track.

- The resulting composite offers controlled resistivity, low friction, and good wear resistance, optimized for sliding contacts rather than soldered terminations.

Characteristics

- Good resistance stability when operated within recommended humidity and temperature limits; elevated relative humidity or condensation can cause drift.

- Low mechanical wear, supporting many millions of wiper operations in servo potentiometers.

- Electrical noise and linearity are optimized by formulation, making conductive plastic attractive in precision position sensors and volume controls.

Typical Uses

- Servo potentiometers and position sensors in control systems, aerospace, and industrial drives.

- High‑reliability adjustable resistors where wear and contact noise must be minimized over lifetime.

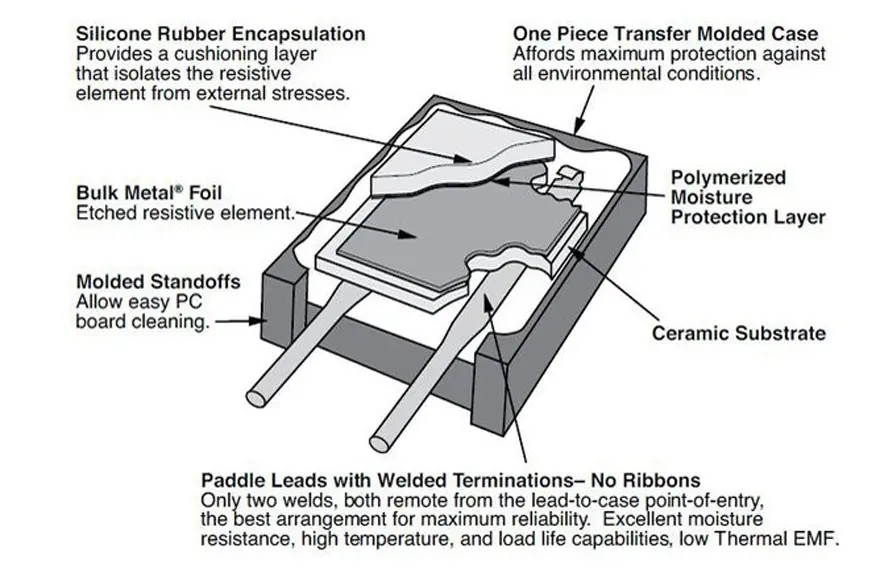

Metal Foil Precision Resistors

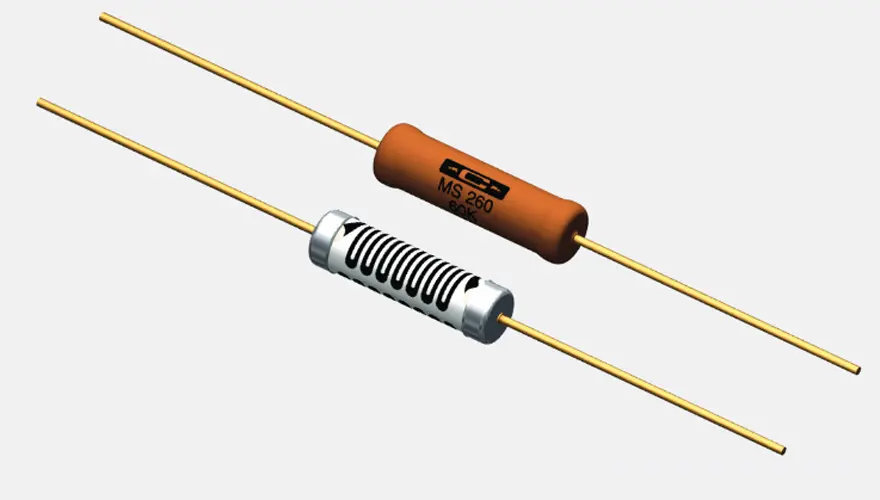

Within the metal film technology there is a particular type of precision resistor made by metal foils, by the inventor, Vishay, called Bulk metal foil. These resistors exist both in axial and radial designs for hole mount, further as SMDs, networks and power styles, finally also in PTC designs.

Construction

Figure 9. shows a principle cutaway view of a foil resistor from the manufacturer VPG foil resistors. The etching pattern is not shown.

Metal foil precision resistors use an ultra‑thin metal foil bonded to a stable substrate:

- A resistive alloy foil (e.g. NiCr‑based) is bonded to a ceramic or glass‑ceramic substrate with carefully controlled adhesive systems.

- The foil is photo‑etched into a meander pattern; laser trimming defines value without introducing deep cuts that would compromise stability.

- Special compensation patterns and composite substrates are used to minimize TCR and thermo‑mechanical strain.

Electrical Performance

- TCR: Ultra‑low TCR, often in the single‑digit ppm/°C range or even below, across wide temperature ranges.

- Stability: Ultra‑low long‑term drift; some products specify drift in tens of ppm over thousands of hours.

- Noise: Virtually no excess noise beyond Johnson noise, making them suitable for low‑level signal paths and precision analog circuits.

- Linearity: Excellent, with minimal resistance change under applied voltage and power (low VCR and PCR), critical in precision measurement.

Advantages

- Unmatched combination of low TCR, low drift, and low noise across a wide temperature and power range.

- Very predictable behavior under thermal cycling and load, making them ideal for precision calibration and reference networks.

Limitations

- Higher cost than standard film or metal element resistors, limiting use to circuits where performance justifies expense.

- Power ratings are typically modest compared with dedicated power or shunt resistors; thermal design remains important.

Typical Uses

- High‑end precision instrumentation, including bridge networks, transducer conditioning, and metrology equipment.

- Precision references and gain‑setting networks in ADC/DAC front ends and operational amplifier circuits.

- Aerospace, medical, and high‑reliability systems where minimal drift over life is critical.

Reference Table: Key Characteristics and Typical Applications

The table below summarizes the main characteristics and typical uses of the resistor technologies discussed in this article.

| Technology | Typical power range (single part) | Typical TCR trend | Noise tendency | Surge / pulse behavior | Inductance tendency | Typical applications |

|---|---|---|---|---|---|---|

| Metal element (shunt/power) | 0.25 W to >100 W (chassis mount) | Low–medium (≈20–200 ppm/°C) | Low | Very good for longer pulses and overload; check short‑pulse data | Medium–high; special patterns reduce | Power and current sense, braking and load resistors, inrush/surge limiters, automotive and industrial power stages |

| Metal oxide / metal glaze | 0.25 W to several watts | Medium (≈±200…±1000 ppm/°C) | Low (better than carbon films) | Very good surge and high‑voltage overload capability | Medium; serpentine spirals mitigate | High‑voltage dividers, surge‑resistant droppers, snubbers, replacements for carbon composition in many designs |

| Carbon film | 0.125 W to 2 W | Strongly negative (≈–250…–1000) | Medium–high, rising with value | Excellent for low‑ohmic, thick‑film pulse loads (esp. non‑spiral) | Medium (spiral film) | Cost‑sensitive general purpose, simple pulse and protection circuits, high‑ohmic hermetic parts for leakage‑critical applications |

| Carbon composition (homog.) | 0.25 W to 2 W (legacy) | Strongly non‑linear | High | Low inductance; internal contacts limit safe pulse energy | Very low | Legacy and safety‑critical designs, special pulse circuits in older equipment, applications where non‑catastrophic failure mode was specifically required |

| Conductive plastic (pot track) | N/A as fixed; 0.25–2 W as pot | Moderate, tailored by formulation | Low–medium (optimized for pots) | Not intended as discrete surge resistor | Very low | Servo potentiometers, precision position sensors, low‑noise adjustable resistors |

| Metal foil precision | 0.05 W to ~1 W | Ultra‑low (often <5 ppm/°C) | Very low (near pure Johnson noise) | Not designed for high‑energy surges; respect derating curves | Very low | Precision references, instrumentation amplifiers, gain‑setting and bridge networks in high‑reliability and high‑accuracy systems |

Conclusion

Metal element, metal oxide/glaze, carbon‑based, conductive plastic, and metal foil resistors each occupy a distinct niche, and selecting the right type depends on whether power, surge, precision, or cost is the primary driver. Metal element and metal oxide/glaze parts dominate in power, surge, and high‑voltage roles, while carbon film and remaining carbon composition types are now mostly reserved for cost‑sensitive, legacy, or specific pulse‑shaping designs. Conductive plastic is the material of choice for low‑noise, long‑life potentiometers, and metal foil resistors remain the benchmark where ultra‑low TCR, drift, and noise justify their premium in high‑end precision and high‑reliability electronics.

FAQ: Carbon, Metal Element, Metal Oxide, Metal Foil and Conductive Plastic Resistors

Such technologies covered in this article compares carbon film, carbon composition, metal element (shunt and power), metal oxide and metal glaze, conductive plastic, and metal foil precision resistors. It focuses on their construction, power handling, TCR, noise, surge and pulse performance, and typical applications.

Metal element resistors are ideal for low‑ohmic, high‑power applications such as current sense, braking, load, and inrush limiting. They offer very low resistance, high power density, good long‑term stability, and strong overload capability, but their construction can be inductive at high frequencies.

High‑voltage and surge‑resistant resistors. Metal oxide and metal glaze resistors use an inorganic film on a ceramic substrate and provide good surge performance, high‑voltage capability, and low noise. They are widely used in high‑voltage dividers, surge‑resistant droppers, snubbers, and as safer replacements for legacy carbon composition parts.

Carbon film resistors offer a wide resistance range and good pulse capability, especially in low‑ohmic, thick‑film non‑spiral versions. However, they have strongly negative TCR, higher noise than metal film or metal oxide, and lower long‑term stability, so they are mainly used in cost‑sensitive designs and certain pulse or high‑ohmic applications.

Legacy and pulse applications

Homogeneous carbon composition resistors are now mostly used in legacy equipment, safety‑critical circuits, and special pulse applications. They provide extremely low inductance and gradual failure modes, but suffer from high noise, poor long‑term stability, and limited safe pulse energy, so they are rarely chosen for new designs.

Conductive plastic in potentiometers

Conductive plastic is a carbon‑loaded thermoset material primarily used as the track in potentiometers rather than as fixed resistors. It offers good resistance stability in controlled environments, very low wear, and optimized noise and linearity, making it suitable for servo potentiometers and precision position sensors.

Metal foil resistors use an ultra‑thin metal foil etched on a stable substrate to achieve ultra‑low TCR, extremely low drift, and very low noise. They are used in precision instrumentation, reference and gain‑setting networks, and high‑reliability systems where long‑term accuracy and stability justify their higher cost.

Metal element and metal oxide/glaze resistors provide the best combination of power and surge handling, especially for longer pulses. Carbon film can handle strong short pulses at low resistance values, while carbon composition is low‑inductance but easily damaged by high surge energy; metal foil is not intended for high‑energy pulses and must follow conservative derating.

Metal foil resistors deliver the highest precision and lowest noise, followed by high‑quality metal film types not detailed in this article. Among the families covered, metal foil is the preferred choice for metrology, precision analog front ends, and reference networks, while metal oxide offers a good compromise of low noise and robustness for less demanding accuracy.

The reference table in the article summarizes power range, TCR trend, noise behavior, surge and pulse performance, inductance tendency, and typical applications for each resistor technology. Designers can use this table to shortlist suitable resistor families before selecting specific series and footprints.