This article written by Teddy Won, KYOCERA-AVX Components Corporation, discusses shortcomings and replacing of aluminum electrolytic capacitors with tantalum capacitors or ceramic MLCC capacitors.

Introduction to Electrolytic Capacitors

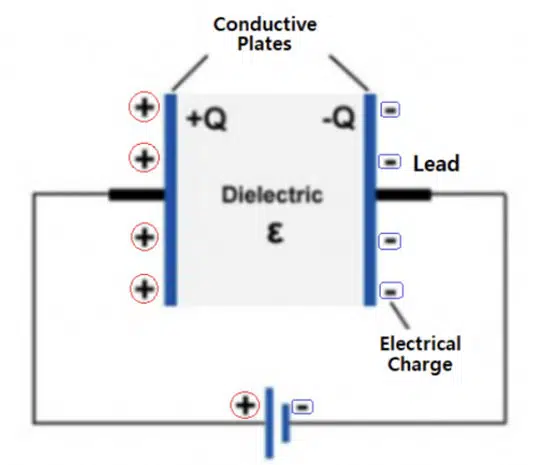

Like all capacitors, electrolytic capacitors (shortly electrolytics or e-caps) are based on the principle of storing energy in an electric field using a voltage applied across a dielectric.

The basic structure of this arrangement is shown in figure 1, where two metallic plates are used to contact the dielectric.

Electrolytic capacitors are unique in that the dielectric is formed by growing an oxide on the surface of a metallic (typically aluminum or tantalum) foil.

This oxide acts as a unidirectional insulator and gives the electrolytic capacitor its polarized characteristic. An electrolyte (typically liquid) is employed to interface with the irregular and rough oxide surface to make electrical contact with the other side of the oxide layer.

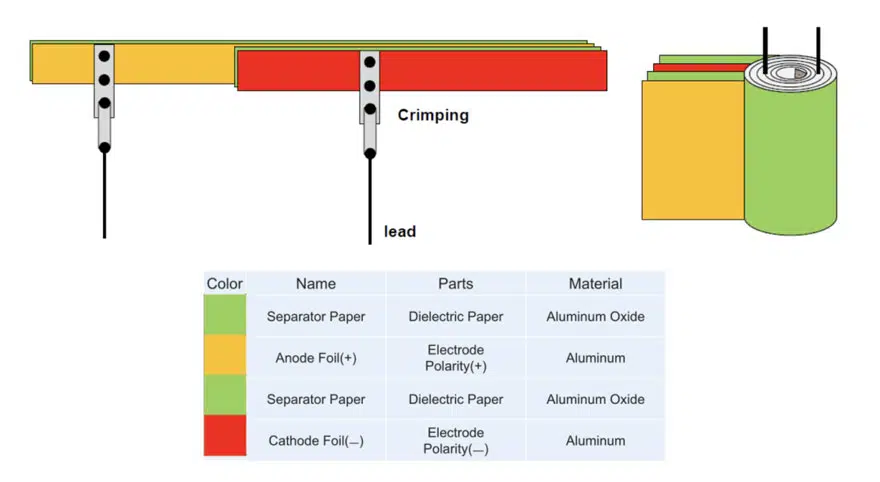

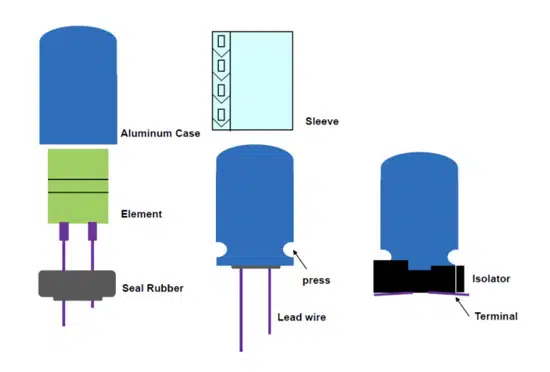

Figure 2 shows that the foil-oxide-electrolyte foil structure is crimped into two wire leads and rolled to form the internal capacitor structure. It is worth noting that the electrolyte is often impregnated within a paper substrate for manufacturing purposes.

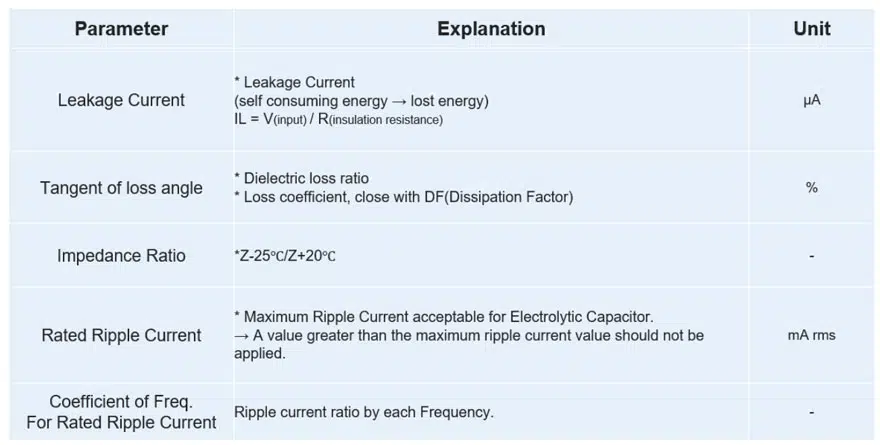

The impedance ratio describes the linearized temperature sensitivity of the impedance. Aluminum electrolytic capacitors often exhibit poor temperature sensitivity making them difficult to design into harsh environments. The rated ripple current is a limiting value that restricts an output ripple current below a certain level to prevent damage from self-heating.

This is intimately coupled to ESR since the internal resistance is the source of self-heating. Finally, the frequency coefficient for rated ripple details the acceptable ripple currents across different frequency ranges. In switching converter applications, knowledge of the frequency dependence is critical for selecting output capacitors. Table 1. provides overview of the most common capacitor electrical parameters such as DCL Leakage Current, DF Dissipation Factor (= tangent of loss angle tgd), Impedance and Ripple Current.

The Shortcomings of Aluminum Electrolytic Capacitors

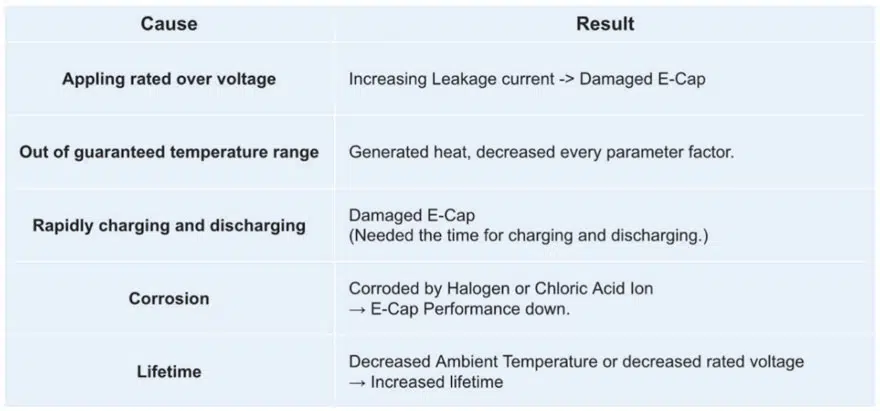

Just like any other capacitor technology, aluminum electrolytics exhibit sensitivities that are undesirable in certain applications and must be accounted for during component selection. While their voltage ratings can be extremely high, they are generally sensitive to heat. In addition, due to a relatively high internal resistance, aluminum electrolytics require charge and discharge rates to be controlled concerning self-heating.

Finally, aluminum electrolytics can be sensitive to corrosion and have a relatively limited lifetime compared to other capacitor structures. These qualities are summarized in table 2. In high-reliability applications, such as automotive, Aluminum electrolytics can pose additional challenges. Their physical structure makes them sensitive to vibration induced failure modes. Special lead and case designs must be employed in these environments.

In addition, commonly used liquid electrolytes can introduce additional failure modes when external temperatures induce vaporization. When combined with the large physical size of aluminum electrolytics, and their relatively high variation specifications, they generally become unattractive for high-reliability applications.

Replacing Aluminum Electrolytic Capacitors

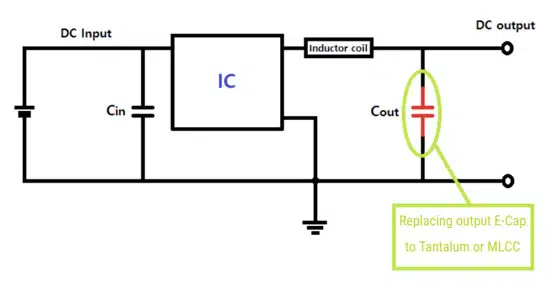

Designs are often required to meet certain regulatory standards that specify performance around reliability, environment, and performance. These must be reconciled with traditional concerns of size and cost. As a simple example, consider the output smoothing capacitor shown in the DC/DC converter design in figure 4.

The configuration of the output capacitor in figure 4 has a fixed and known polarity. That allows aluminum electrolytics, tantalum or multilayer MLCCs to be possible candidates for use. If the application demands long life, extreme temperature tolerance, or small physical size, then traditional aluminum electrolytics may not be optimal. As shown in figure 5, if a large bulk capacitance and low voltage are required, then the tantalum option may be preferable. If the voltage is particularly high or ripple performance is critical, then several low ESR MLCCs in parallel may be suitable.

Conclusion

Given cost requirements and any other specific performance demands, there exist a wide variety of capacitor options that could readily replace the aluminum electrolytic capacitor.

Table 3 presents a high-level comparison between MLCC, aluminum electrolytic, and tantalum capacitors. Whenever lifetime reliability, temperature stability, or size are of paramount importance, one should consider replacing aluminum electrolytic capacitors in a design with MLCC’s or tantalum devices. Multiple MLCC’s may be necessary to achieve the required capacitance, and the bill of material costs might require adjustments for tantalum devices, but the resulting performance will justify the change.