As AI servers and GPU accelerators push to higher performance and power density, their power delivery networks are undergoing a major architectural shift. Designers are increasingly replacing aluminum polymer capacitors with advanced multilayer ceramic capacitors (MLCCs) to meet stringent requirements for transient response, footprint, and reliability according to Samsung Electro-Mechanics post.

Rising Power Demand in AI Servers

Modern AI servers integrate multiple high‑power GPUs and custom accelerators, which generate large, fast load transients on the power rails. Traditional aluminum polymer capacitors struggle to keep pace with these dynamic profiles, especially as switching frequencies rise and board space becomes constrained. This environment favors capacitors that offer low impedance at high frequencies, compact size, and high capacitance density.

Why MLCCs Are Replacing Aluminum Polymer Capacitors

- Smaller size and lower height: MLCCs provide high capacitance in a compact form factor, making them ideal for dense GPU modules and low‑profile server cards.

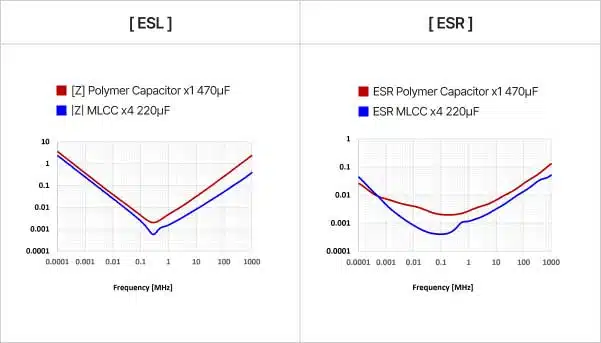

- Excellent high‑frequency characteristics: Very low ESR and ESL enable MLCCs to handle fast current transients and reduce voltage droop during GPU load steps.

- Improved board utilization: By configuring multiple MLCCs in parallel, designers can implement the required bulk capacitance while freeing PCB area for signal routing and thermal solutions.

- Robust supply chain: A broader supplier base and mature manufacturing ecosystem contribute to more stable sourcing compared to aluminum polymer capacitors.

Impact on Power Delivery Network Design

In AI server VRMs and GPU power stages, the combination of higher switching frequencies and large transient currents demands capacitors that remain effective in the 1–2 MHz range. MLCCs excel here due to their low impedance characteristics, which improve output voltage stability and reduce the magnitude and duration of undershoot and overshoot during load steps.

At the same time, strict mechanical and thermal constraints in GPU boards and server motherboards favor lower component profiles. MLCC‑based solutions help designers maintain or even reduce module height while meeting target capacitance and ripple current specifications.

High-CV Mid-to-Large MLCCs for AI Applications

Recent advances in Samsung Electro-Mechanics high‑CV mid‑to‑large MLCCs have opened up application areas that were previously dominated by aluminum polymer capacitors. These high‑capacitance devices, available in popular case sizes such as 0603, 1206 and 1210, support low‑voltage rails commonly used in AI GPU cores and memory systems.

| Part Number | Size (inch/mm) | Capacitance | Rated Voltage | TCC | Data Sheet | Samples |

|---|---|---|---|---|---|---|

| CL10X107MS8NZW# | 0603 / 1608 | 100 µF | 2.5 Vdc | X6S | Download | Available |

| CL31X227MRKNNW# | 1206 / 3216 | 220 µF | 4.0 Vdc | X6S | Download | Available |

| CL31A227MQKNNW# | 1206 / 3216 | 220 µF | 6.3 Vdc | X5R | Download | Available |

| CL31Z107MRKN4N# | 1206 / 3216 | 100 µF | 4.0 Vdc | X7T | Download | Available |

| CL32X337MSVN4S# | 1210 / 3225 | 330 µF | 2.5 Vdc | X6S | Download | Available |

| CL32Z227MSVN4S# | 1210 / 3225 | 220 µF | 2.5 Vdc | X7T | Download | Available |

Design Takeaways for Power Engineers

- Use parallel MLCC banks near the GPU or AI accelerator to minimize loop inductance and improve transient response.

- Select MLCCs with appropriate voltage derating and temperature characteristics (e.g., X6S, X5R, X7T) for the target rail and environment.

- Validate impedance and ripple performance at the actual switching frequency range of the VRM, not only at low frequencies.

- Consider mechanical constraints and PCB warpage when deploying high‑capacitance MLCC arrays in tight layouts.

By leveraging high‑CV MLCCs in mid‑to‑large case sizes, AI server and GPU designers can build more compact, efficient, and robust power delivery networks that keep pace with the rapid evolution of AI workloads.