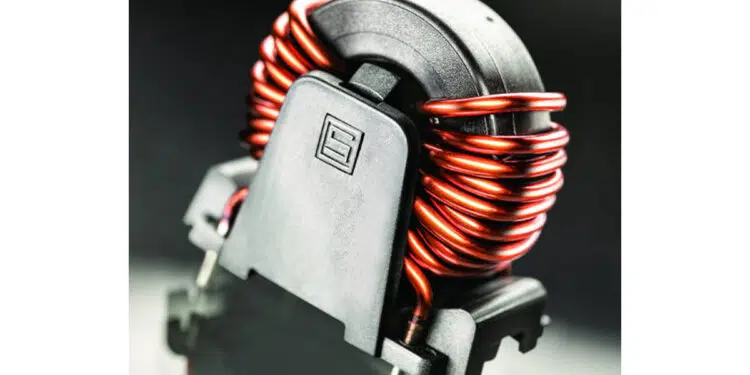

SCHURTER expands the range of successful, current-compensated chokes with a series for 1-phase high-current applications on printed circuit boards. Due to the vertical design, the new DKIV-1 series requires a significantly smaller footprint. The chokes are available with ferrite or nanocrystalline cores for rated currents from 10 A to 50 A. The open design makes the chokes particularly compact and lightweight.

Like all other aspects of electronic design, the power section is oftentimes built today using discrete components on printed circuit boards. With the trending integration of components, to achieve smaller and smaller form factors, thermal problems and high currents on the PCB can become a challenge. Traditional block filters might well address these challenges, but their larger package size also presents challenges due to the mentioned space constraints; therefore an asymmetrical effective common mode choke and capacitors mounted on the PCB is a better solution.

Compact and lightweight

The new DKIV-1 series is designed for 1-phase applications at rated currents from 10 A to 50 A. Despite the high currents, the vertical choke requires only a small footprint on the PCB. This allows a compact design with high performance. The current-compensated chokes are compact and lightweight. The contacting is made by means of through-hole contacts (THT).

The combination of a vertical choke (DKIV) with a horizontal choke (DKIH) in multistage filters reduces mutual interference of the magnetic fields of the individual chokes.

Performance and approvals

The DKIV-1 current compensated chokes comply with IEC 60938 and with a rated voltage of 300 VAC or 450 VDC, they are suitable for almost any application. The DKIV-1 series is certified for current ratings from 10 to 50 A, 300 VAC according to IEC and UL and 10 to 50 A, 250 VAC according to CSA. The chokes have ENEC and cURus approvals. The DKIV-1 have been designed for a wide temperature range from -40 °C to +100 °C.

Key Features

- Compact size and light weight

- Small footprint on PCB

- Open design optimizes heat dissipation

- Nanocrystalline or ferrite ring cores