Taiyo Yuden has expanded its MCOIL multilayer metal power inductor portfolio with a new AEC‑Q200 qualified 1608 size device capable of operation up to 165 °C, aimed at demanding automotive power supply designs.

The new inductor targets choke coil roles in compact DC‑DC converters where shrinking PCB area, higher switching frequencies, and harsher thermal conditions are pushing conventional ferrite solutions to their limits.

Key features and benefits

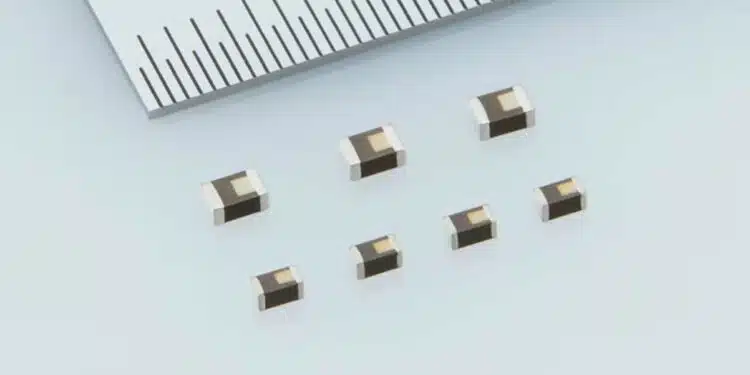

The new part is introduced as MCOIL LACNF1608KKT1R0MAB, a multilayer metal power inductor in 1608 size (1.6 mm × 0.8 mm footprint, 1.0 mm maximum height). The product is part of the LACN series and is qualified to the AEC‑Q200 reliability test standard for passive automotive components, making it suitable for use in ECUs and other mission‑critical modules where automotive qualification is mandatory.

Key characteristics and benefits include:

- Compact 1608 case size (1.6 mm × 0.8 mm × 1.0 mm max height), helping designers increase power density and free up PCB area in crowded automotive control units.

- Operating temperature range of −55 °C to +165 °C, enabling stable operation in engine bay and other hot‑zone installations where board temperatures can exceed the 125–150 °C range of many legacy parts.

- Multilayer metal composite construction (MCOIL), using proprietary metal materials bonded with oxide films through heat treatment to ensure insulation, high heat resistance, and good thermal conductivity; this supports both high current handling and robust reliability under thermal cycling.

- AEC‑Q200 qualification, simplifying approval workflows for automotive OEMs and Tier‑1 suppliers compared with non‑qualified commodity inductors.

- Stable inductance characteristics and high reliability even under high‑temperature conditions, which helps maintain control loop stability and converter efficiency over the vehicle lifetime.

For engineers, the high upper temperature limit means less derating margin is consumed by worst‑case ambient and self‑heating, which can allow either a smaller inductor for the same current or higher allowable ripple current within the same footprint.

Typical applications

Taiyo Yuden positions the new 1608 LACNF device as a choke coil for DC‑DC converters in a broad range of automotive systems. These converters are increasingly used to generate multiple local rails for digital, sensor and actuator loads from a common 12 V or 48 V supply in modern vehicles.

Typical applications include:

- Engine control systems: engine ECUs and related modules placed in hot environments close to the engine, where sustained high temperatures and vibration demand robust magnetics.

- Safety systems: ABS and other safety‑related control units that require stable power conversion for microcontrollers, sensors, and actuators under extreme ambient conditions.

- Body and ADAS systems: advanced driver assistance systems, camera and radar modules, and body control electronics that combine tighter packaging with higher processing power, driving up power density requirements.

- Information and cluster systems: instrument clusters and infotainment units where multiple DC‑DC converters supply SoCs, displays and communication ICs, and where space savings and low profile components are critical.

The combination of compact footprint, 1.0 mm maximum height, and 165 °C rating makes this inductor particularly attractive in densely populated multilayer automotive PCBs with severe thermal constraints and limited vertical clearance.

Technical highlights

The press release introduces a lineup of 14 items in the MCOIL LACN series, with LACNF1608KKT1R0MAB highlighted as the 1608 size addition. The detailed electrical characteristics (inductance, DCR, current ratings) are provided in the manufacturer’s datasheet and online tools; designers should always refer to those documents for exact values rather than using generic assumptions.

Important technical aspects include:

- Structure: multilayer metal power inductor using proprietary metal material layers bonded by oxide films. This structure allows efficient heat conduction through the body and robust insulation between layers, which in turn supports the high maximum operating temperature.

- Current rating definition: Taiyo Yuden specifies saturation current (Idc1) as the DC current at which inductance drops by 30 % (at 20 °C), and temperature‑rise current (Idc2) as the DC current that causes a 40 °C temperature increase (at 20 °C). The rated current is the DC current that simultaneously satisfies both limits.

- Product families: the newly added device is part of the LACN series for AEC‑Q200 applications; related LCCN series versions with IEC/JIS specification part numbers are also available for other segments, sharing similar construction but with different qualification focus.

In practice, understanding the distinct current ratings is essential: in high‑ripple DC‑DC stages, saturation current usually limits transient performance, while temperature‑rise current constrains continuous load and ambient temperature combinations. Designers should check both curves in the datasheet when selecting a part for borderline thermal environments.

Availability and part numbers

According to the press information, Taiyo Yuden has commercialized 14 LACN series items including the LACNF1608KKT1R0MAB 1608 inductor, with mass production already started at the company’s Wakayama Taiyo Yuden manufacturing site. Samples are quoted at 50 JPY per unit, giving purchasing teams a rough indication of relative price positioning compared with larger or lower‑temperature inductors in the same family.

Key commercial points:

- Product series: MCOIL LACN series (AEC‑Q200 qualified multilayer metal power inductors).

- Highlighted part number: LACNF1608KKT1R0MAB (1.6 mm × 0.8 mm × 1.0 mm max, automotive grade, −55 °C to +165 °C).

- Production status: in mass production, with samples available to support evaluation and early design‑in.

- Related series: LCCN series with IEC/JIS specification part numbers for applications that do not explicitly require AEC‑Q200.

For full ordering information, available inductance values, and packaging options, engineers and buyers should consult the online LACN series overview and the individual datasheets provided by Taiyo Yuden.

Design‑in notes for engineers

While the new 1608 MCOIL device is drop‑in from a footprint perspective, careful electrical and thermal design is still required to fully exploit its −55 °C to +165 °C rating in real automotive hardware.

Points to consider during design‑in:

- Thermal environment and derating: even though the part is rated up to 165 °C, current derating versus ambient temperature still applies; engineers should apply the manufacturer’s derating curves and consider worst‑case board temperatures in engine bay or under‑hood locations.

- DC‑DC converter topology: in typical step‑down converters for ECUs or ADAS modules, select the inductance value to meet ripple current targets and transient response needs, then confirm that peak and RMS currents remain below both saturation and temperature‑rise current limits across the operating range.

- Layout and cooling: leverage the device’s good thermal conductivity by connecting pads to sufficiently large copper areas, possibly with thermal vias to inner planes, to reduce temperature rise at high current; this is especially important in high‑density modules with limited airflow.

- EMC behavior: metal composite inductors typically exhibit lower acoustic noise and can improve EMI performance versus some wire‑wound alternatives; nonetheless, final EMC must be verified at system level, and snubbers or additional EMI filters may still be required.

- Qualification and documentation: for automotive projects, retain the AEC‑Q200 qualification information and test reports from Taiyo Yuden as part of the PPAP or component approval package, and ensure that internal component libraries flag the part as automotive grade.

When migrating an existing design from a larger footprint or lower temperature‑rated inductor, the new LACNF1608KKT1R0MAB can support further miniaturization and higher local power density, provided the converter’s switching losses and board‑level thermal management are adequately handled.

Source

This article is based on information provided in the official Taiyo Yuden press release announcing the commercialization of the MCOIL LACN series multilayer metal power inductors including the new LACNF1608KKT1R0MAB 1608 size component, complemented by publicly available series overview information and general manufacturer documentation.