Tantalum, with its unique properties enabling high performance, reliability and long life in many essential applications, is now available for use in the rapidly expanding metal Additive Manufacturing (AM) space. Size of the particles may not be suitable for capacitor electrodes as of yet, nevertheless the latest status of AM technology and its applications is described in this article by Global Advanced Metals.

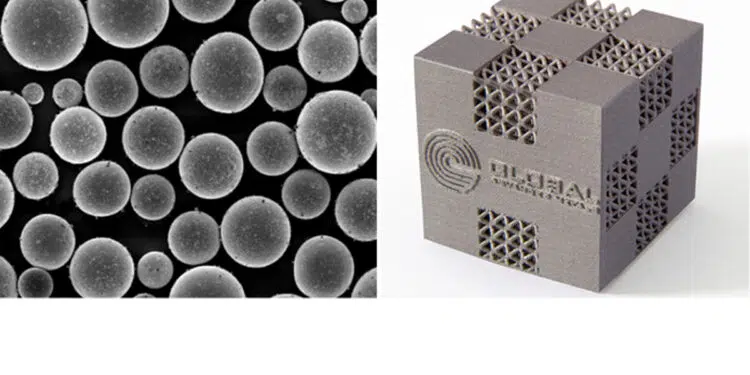

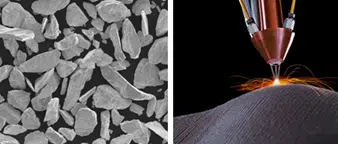

AM technologies include various forms of 3D printing using “spherical” powder and of cold spray techniques using “angular” powder types (both types depicted below). Metal AM is the opposite of subtractive manufacturing, where shapes are milled and forged and cut from large starting pieces of metal. AM technology advantages typically include eliminating waste, enabling new designs and pro-typing, providing rapid creation of replacement parts, the creation of complex geometries and “light-weighting” and providing repair at point of use. Tantalum, it’s unique properties now coupled with AM capable flexibility, is being developed in an expanding range of applications in defense, medical, industrial and other industries.

In 3D printing, layers of spherical powder are bonded together with the powder layer thickness related to the particle size. Typical particle sizes depend on the 3D printing method and cover diameters from less than 15 microns, 15 to 45 microns, and 50 to 150 microns. For perspective, a human eye typically cannot see things smaller than 50 to 60 microns. Powder properties are often customized for common AM printer technologies including laser powder bed fusion (LPBF), direct energy deposition (DED), electron beam melting (EBM), binder jetting, and metal injection molding (MIM). Spherical tantalum for 3D printing is developing in a broad variety of industries and applications including medical implants, valve bodies and heat exchangers in the chemical processing industry’s harsh environments, radiation shielding in aerospace applications and various defense related products.

Another AM technology is gas dynamic cold spraying or cold spray (CS), which is best described as a high-energy coating deposition process where solid and typically angular metal powders are accelerated in a supersonic gas jet onto a substrate. The particles can travel up to 1200 meters per second as they strike the substrate, plastically deform, and bond to the surface of the substrate. While similar to thermal spraying, cold spray utilizes the expansion of gas to achieve supersonic speeds and the powders are not melted. This results in favorable bonding properties such as no heat affected zone, practically unlimited deposition thickness, high bond strengths, and high deposition efficiency. Tantalum powders used in cold spray are typically angular with particle sizes less than 50 microns and can be customized for different CS machines. Tantalum sprayed utilizing CS finds favor in coating substrates for the defense, energy, space, and chemical processing industries.

With the confidence found in existing and emerging stable tantalum ore sources to feed the growing global tantalum demand (for additional details, read Passive Components Blog’s “Tantalum in Electronics” and “Tantalum for a Lifetime” Articles – Global Advanced Metals), academia and industry have the opportunity to design, test, develop and implement with tantalum using these AM technologies of 3D printing with metal powders and cold spray. These are indeed exciting times for tantalum and its use in a wide variety of industries now including these two new AM and emerging technologies which open the possibilities to novel products, improved performance and elimination of waste.