Hardware electronic designers can use a conventional fuse, or they can use a fusible resistor to protect their circuits. What will work best in the specific application?

Chargers and external power supplies are essential devices for consumer electronics, especially mobile and wearable products. Keeping them powered and charging them fast is very important to the end-users. Example products include tablet computers, personal computers, mobile phones, gaming devices, mp3 players, wireless smartwatches, headphones, fitness monitors and medical monitors. Downtime to recharge these devices interrupts usage, and consumers need faster recharge times for maximum uptime of their devices.

Faster charging requires a higher power charger or power supply. Higher power requires designers to put greater emphasis on safety while being challenged by cost and size constraints and more stringent efficiency requirements. While most designers realize they need overcurrent protection for their charger or power supply, they may not know that they can take two different approaches to incorporate overcurrent protection into their design.

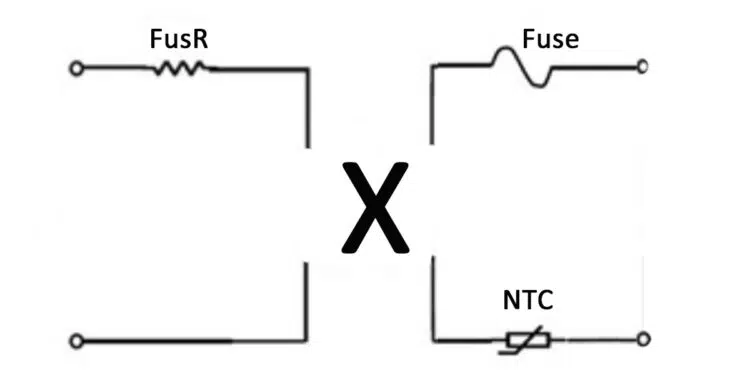

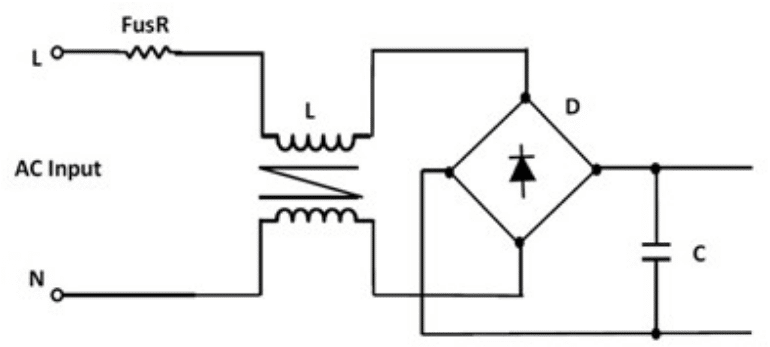

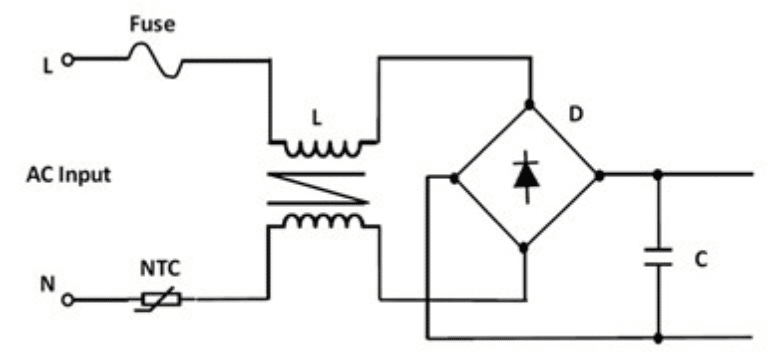

Designers can use a fusible resistor (Figure 1a) or they can use a conventional fuse (Figure 1b)

Fusible resistors combine the benefits of overcurrent protection and inrush current protection in one component. However, fusible resistors respond differently to overcurrents and have other impacts on charger and power supply efficiency than fuses.

KEY DIFFERENCES IN BRIEF

Fuses: Reducing the risk of fire by opening at lower temperatures

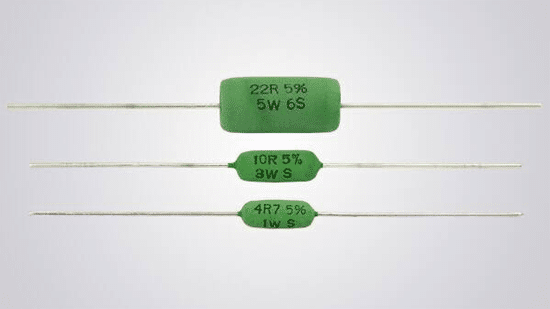

A fusible resistor opens up like a fuse when its current rating is exceeded. The component is generally a nichrome element with a melting temperature of around 1400° C. Nichrome has a low thermal coefficient of resistance that allows the resistor to have a stable resistance over temperature. The 1400° C melting temperature allows surrounding components and the PC board to get hot during an overcurrent condition.

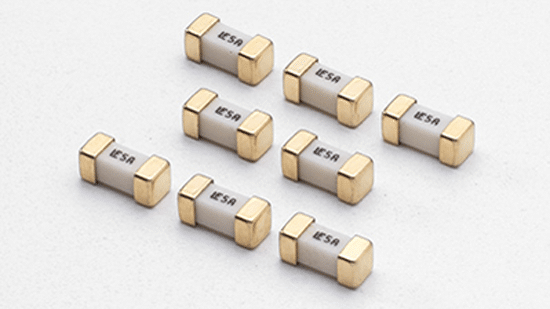

Fuses are generally copper or silver elements with a melting temperature typically between 962° C and 1083° C. Fuses also have a high thermal coefficient of resistance, at least a factor of 10 higher than a nichrome fusible resistor. As a result, the temperature of a fuse will increase faster when an overcurrent condition occurs. The fuse’s resistance rises more quickly, bringing the fuse to its melting point sooner. A fuse prevents a heat build-up that would otherwise occur when a fusible resistor is subject to an overcurrent condition. The higher heat generated by the fusible resistor can damage other components and potentially lead to the ignition of combustible components near the fusible resistor.

Fusible resistors: Two functions in one package

The primary benefit of using a fusible resistor is that its resistance function provides a limitation on inrush current. A fusible resistor used as the main overcurrent component in a power supply or charger (as shown in Figure 2a) can have a resistance of 10 Ω. A fuse, in contrast, has a resistance in the milliohms to 100s of milliohms range. Designers can use a fuse and an NTC thermistor to obtain equivalent overcurrent protection and inrush current limitation (Figure 2b). An NTC thermistor has a resistance that can be as high as 10 or 20 Ω initially; however, it falls into the 10s of milliohm range during steady-state operation of the power supply.

Fusible resistors appear to offer space-saving over using separate fuses and thermistors. However, the heat generated by fusible resistors could require spacing between components. Fusible resistors rated up to 10 W require other parts to be at least 0.5 inch away. If rated above 10 W, and 1 inch spacing is needed. When chargers and power supplies need to be in small, compact packages, the necessary spacing required around the fusible resistors could leave the circuit designer with inadequate space for the complete design.