Source: TTI Market Eye article

by Murray Slovick

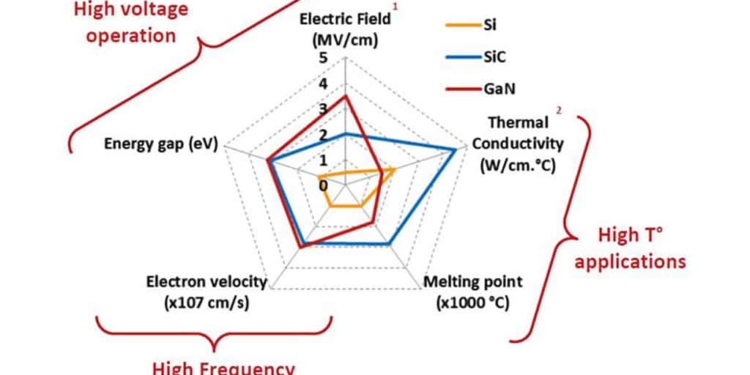

All other parameters being equal, wide bandgap (WBG) semiconductors are preferred over narrow band semiconductors (such as silicon) for electronics applications because the large energy separation between the conduction and the valance bands allows these devices to operate at elevated temperatures and at higher voltages. Compared to the relatively narrow bandgap of 1.1eV of the industry stalwart Si, Gallium Nitride (GaN), for example, has a bandgap of 3.4eV.

Bandgaps measure how much energy is required to push an electron into a conducting state; a bigger bandgap enables a material to withstand a stronger electric field so components can be thinner (for a given voltage), lighter, and handle more power than parts consisting of materials with lower bandgaps.

Semiconductors with a larger bandgap have been developed for applications where Si cannot provide sufficient power density to achieve the necessary results. In particular, Silicon Carbide (SiC), and GaN have led to tremendous advances in power switching and/or power amplifier applications. Beyond these recognized markets, lidar sensors for autonomous vehicles and motion control for robotics are other emerging areas. SiC MOSFETs also are commonly found in cell phone applications, and GaN power transistors have found applications in 600 V market segments such as data center server power supplies.

Now that the availability and performance of wide-bandgap semiconductors in the marketplace has been established, at the upcoming APEC 2019 in Anaheim a “rap session” will be held to answer the question “when will WBG have significant volume?” Addressing this issue will be manufacturers selling SiC and GaN components, and the companies designing current and future products with them.

But just as SiC and GaN establish themselves, here comes another semiconductor with an even larger bandgap. The wide-bandgap semiconductor gallium oxide (Ga2O3) is potentially the next generation device for power conversion systems such as Schottky barrier diodes (SBDs) and FETs. Schottky rectifiers made on wide bandgap semiconductors have fast switching speed, important for improving the efficiency of motor controllers and power supplies, as well as low forward voltage drop and high temperature operability.

The bandgap of Ga2O3 – the energy needed to power an electron to the point where it is conductive – is 4.4 to 4.9eV depending on the crystal structure, which represents a major increase over both GaN and SiC. There are, of course, other semiconductors with even wider bandgaps, such as aluminum nitride (AlN) and diamond but so far these are of interest only to the academic community.

Gallium oxide is expected to be particularly useful in high-power and high-frequency devices. It can also be produced directly from its molten form, unlike other semiconductors, enabling high-quality crystals to be manufactured on a large scale.

Interest in Ga2O3 has grown quickly over the past few years due to its potential as a major candidate for high breakdown voltage device applications. Its use in high power switching is supported by a high critical field strength of about 8 MV/cm. Like GaN, Ga2O3 has a higher critical electric field strength than silicon and its higher electron mobility enables a device to have a smaller size for a given on-resistance and breakdown voltage. This allows devices to be physically smaller.

The initial thrust of Ga2O3 electronics will be targeted at high power converters for both DC/DC and DC/AC applications. Schottky diodes could supplement 600 V Si or SiC rectifiers in switch mode power converters. One should remember that in power switching applications, the operating voltage is limited by the breakdown electric field strength (Ebr) which is the key specification here. The critical field strength of Ga2O3 is more than 20 times that of silicon and more than twice that of SiC and GaN. As a result, it should have the ability to operate at high voltages and at elevated temperatures while generating substantially higher power than the current generation devices. So far the electronic device demonstrations with Ga2O3 have included kV-class Schottky rectifiers with breakdown voltage >1 kV and MOSFETs with critical field strengths larger than typical GaN or SiC values.

Since many critical device parameters improve exponentially with the bandgap value, such improvements can be significant enough to justify the effort to fully develop a new technology. That said, it must be added that Ga2O3 has limitations – it has a very low thermal conductivity when compared to other WBG materials.

For the reasons already mentioned, Ga2O3 may supplement SiC and GaN, but it is not expected to replace them. So what needs to occur for it to play a role alongside the more mature SiC and GaN power device technologies?

As noted, Gallium oxide has poor thermal conductivity. When you make a high-power device, you need to have a good thermal conductivity to extract the heat out of the device. For one thing, the low thermal conductivity of gallium oxide might be mitigated via the substrate or by thinning down the substrate and using a heatsink as well as top-side heat extraction.

Also, remember that it took decades from conception to commercialization of SiC power devices. Similarly, commercial GaN radio frequency (rf) transistors first appeared in 2004, with 100 V devices in 2008 and 600 V devices in 2012. Commercially available SiC and GaN power devices still have a high cost and SiC and GaN cannot be grown from the melt like Si.

GaN and SiC currently cover many of the same voltage ranges, with GaN devices dominating from tens to hundreds of volts and SiC from approximately 1 kV to many kilovolts. Future—near term—voltages for GaN devices should range from commercially available 1200 V devices to experimental devices at 3300 V, while SiC devices will expand down to 600 V. In other words, these technologies are largely complementary and will continue to co-exist. Ga2O3 will not displace these materials, but it can possibly supplement them at higher voltages.

What is more, existing Si, SiC and GaN enjoy tremendous advantages in terms of process maturity, an advantage that is especially true for Si.

For Ga2O3 the journey is at the very beginning as reports and studies of its fundamental properties have just started to emerge. High-efficiency power supplies and power converters are needed for such applications as aircraft electronics, radar and electronic warfare system power supplies, automobile electronics, electric motor controllers, and power conditioning. We’ll update you on developments as they occur.

featured chart source: Research Gate paper: “Improving Multi-Voltage Electrical System Performance with Smart Step-Down Converters” by Amin Emrani and Steve Spadoni Ford Motor Company, link here