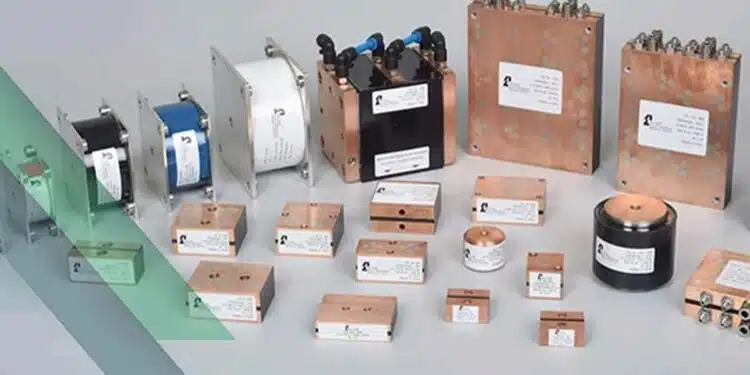

Exxelia power film capacitors are engineered for demanding applications including induction heating, plasma generators, medical equipment, magnetizers, wireless electric vehicle chargers, auxiliary power supplies, and resonant circuits.

The portfolio is tailored to meet the stringent requirements of engineers and procurement specialists in the passive electronics sector.

Many capacitors feature a modular design, allowing for easy parallel and series connections. This facilitates scalable solutions customized to specific power needs.

Key performance specifications include reliable operation over a frequency range of 5 kHz to 1 MHz, with current ratings from 200 to 1250 Arms, voltage ratings from 400 to 1200 Vrms, and power ratings between 150 to 1000 kVAR.

- Induction Heating, Melting, and Forging Applications:

Induction heating systems require components capable of managing substantial ripple currents at medium to high frequencies, with reliability under challenging thermal conditions being essential.

Specialized power film capacitors are utilized in these demanding environments, providing necessary capacitance and current handling for resonant tank circuits. Examples include water-cooled capacitors designed for high reactive power applications and variants optimized for significant current handling at higher frequencies.

- Industrial RF & Plasma Generators:

Radio Frequency (RF) and plasma generation systems operate at high frequencies where low inductance and high Q-factor components are critical for performance and efficiency. Power film capacitors in this category are designed to minimize parasitic self-inductance (ESL) and maintain signal integrity. Water-cooled designs manage thermal dissipation effectively during continuous operation, offering high-Q solutions to reduce energy loss in resonant circuits.

- Traction Inverters and Resonant Converters:

Capacitors for traction inverters and resonant converters are constructed to withstand demanding electrical and environmental conditions typical in transportation and heavy industrial applications. Cooling configurations, including water-cooled and hybrid designs, ensure thermal performance aligns with system requirements.

- High-Frequency Welding and Brazing Equipment:

Welding and brazing equipment operating at high frequencies requires capacitors that manage significant currents efficiently. Capacitor options cater to various cooling strategies, from conduction-cooled designs suitable for systems where direct water cooling isn’t feasible to water-cooled versions for high-power systems demanding optimal thermal efficiency.

These components are engineered to maintain performance and reliability across a range of high-frequency industrial applications.

| Feature | FP-8C-1500 | FP-5F-200 | FP-31-1000 | FP-20-400-SP |

|---|---|---|---|---|

| Primary Area | Induction Heating / Welding | RF & Plasma Generators | Traction / Resonant Converters | Induction / Welding / Brazing |

| Cooling Method | Water Cooled | Water Cooled | Water / Hybrid Cooled Options | Conduction / Water Cooled Options |

| Key Feature | High Current / Power | Low Inductance / High Q | High Power Density / Robust Design | High Frequency / Cooling Options |

| Typical Freq. | Medium to High Frequency | High Frequency / RF | Medium Frequency (Converter specific) | High Frequency (up to 1 MHz) |

Exxlia Power Film Catalogue Download