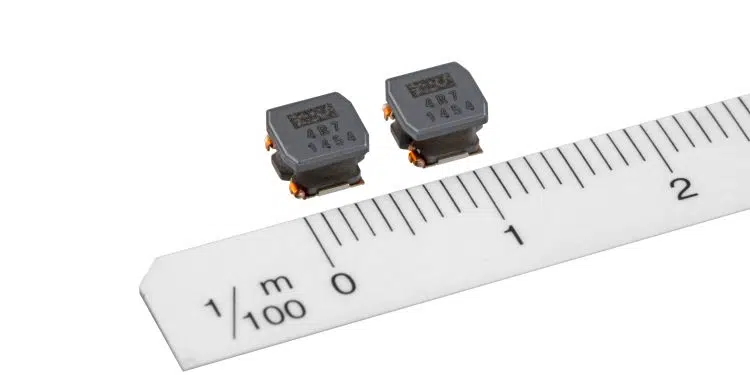

TDK Corporation has announced the introduction of its new VLS5030EX-D type power inductor (5.3 x 5.0 x 3.0mm (L x W x H)) as part of the VLS-EX-D Series of wound ferrite power inductors automotive power circuits.

These compact components provide excellent DC superposition characteristics with an assured performance at temperatures of up to 150℃. These inductors are suitable for headlights, airbags, electric power steering (EPS), advanced driver-assistance systems (ADAS), engine control units (ECUs), and various other power circuit applications.

Mass production of these new inductors began in October 2022.

Recently, there has been a rise in the number of ECUs mounted under the hood for the electrification of various automotive control functions, as well as for infotainment, autonomous driving, and other applications.

The compact components support automotive power over-coax (PoC) implementations with an excellent DC superposition characteristic for transmitting data as well as supplying power, fulfilling the needs of, for example, advanced driver-assistance systems (ADAS) that employ low-voltage differential signaling (LVDS) transmission. In addition, as the IC’s processing capability increases, a higher current is required, and the VLS-EX-D series contributes to these specifications.

The new VLS-EX-D series of inductors achieves a higher-rated current compared to TDK’s standard VLS-EX-H series. These improvements are achieved by using TDK’s innovative metallic magnetic material for the magnetic shielding function. Specifically, for the VLS5030EX-D inductor, the rated Isat is 3.3 A at 4.7 μH, which is an increase of approximately 6 % from standard parts of the same size – 5.3 x 5.0 x 3.0 ㎜ (L x W x H). Moreover, thanks to the welding method used for connecting the wire winding to the external electrodes, high reliability is implemented for reflow and use in high-temperature environments.

TDK will continue expanding the VLS-EX-D series product portfolio to cater to needs for a wide range of automotive applications, centering on ADAS, and will meet the requirements of customers.

Features

- Supporting temperatures of up to 150 ℃ for under-the-hood power circuit applications

- Implementing a DC superposition characteristic with high-rated current by using TDK’s innovative metallic magnetic material for the magnetic shielding function

- Achieving high reliability by employing the wire connection structure in which wires and terminals are welded

- Compliant with AEC-Q200 Rev D for automotive applications

Applications

- Automotive power supply circuits for ADAS, EPS, PoC, various types of ECU, etc.