This article based on Knowles Precision Devices blog discusses decoupling capacitors and benefits of using ceramic capacitors for decoupling.

As you likely know, capacitors are used in electronic circuits to provide local energy storage and stabilize power supply voltage.

Decoupling capacitors are a specific type of capacitor used to isolate or decouple two circuits. In other words, these capacitors decouple AC signals from DC signals or vice versa.

Decoupling capacitors act as a buffer, supplying clean and stable power to components, which minimizes the risks of malfunctions, noise coupling, or signal integrity issues.

How Does a Decoupling Capacitor Work and Why is it Needed?

Decoupling capacitors are primarily used to suppress voltage fluctuations or noise on power supply lines so that there is no impact to the operation of sensitive components.

In power supplies, decoupling capacitors are strategically placed near the power pins of integrated circuits (ICs) or other sensitive components.

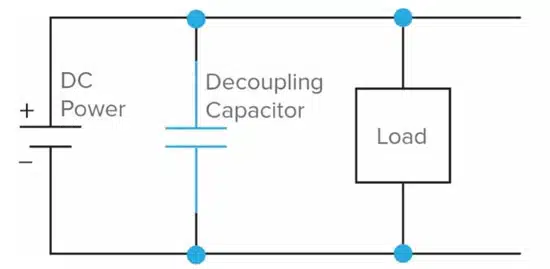

The decoupling capacitors are connected in parallel to the power supply lines and act as a local energy reservoir that can quickly supply or absorb current as needed (Figure 1).

This configuration helps reduce voltage ripple, minimize voltage droops during transient events, and provides a stable and clean power supply to other components.

The Benefits of Using Ceramic Capacitors for Decoupling

Ceramic capacitors are widely used as decoupling capacitors because ceramic poses many favorable electrical characteristics including the following:

- High capacitance in a small form factor: Ceramic capacitors offer high capacitance values in a compact size, allowing for sufficient energy storage capacity in a small form factor. This is especially beneficial when space on the PCB is limited.

- Low equivalent series resistance (ESR): Ceramic capacitors exhibit low ESR, which means they can effectively deliver or absorb current without significant voltage drops. This low resistance allows the capacitor to respond quickly to dynamic changes in current demand, providing immediate energy when needed.

- Low equivalent series inductance (ESL): Ceramic capacitors typically have low ESL, enabling them to offer good high-frequency filtering capabilities. They can effectively suppress high-frequency noise and provide a low impedance path for high-frequency currents.

- Wide frequency response: Ceramic capacitors have a broad frequency response, making them suitable for filtering out a wide range of noise frequencies commonly found in power supply lines.

- Temperature stability: Ceramic capacitors can maintain their capacitance and performance over a wide temperature range, ensuring consistent decoupling performance even in varying operating conditions.

Selecting the Ideal Ceramic Capacitor for Decoupling

There is a lot to consider when selecting the optimal decoupling capacitor for your application including the appropriate capacitance value, voltage rating, and capacitance type, and our team of expert engineers is ready to help you review what will work best for your application. With decades of experience supplying a variety of specialty components for power electronics devices, not just capacitors, we understand your entire electrical system. Therefore, we can work with you to determine proper placement and layout techniques to consider for optimizing the effectiveness of your decoupling capacitors in your power supplies.