This article written by Naotaka Hata, KYOCERA-AVX Corporation provides SMD capacitor technologies benchmark in DC-DC converter applications. This whitepaper outlines the critical distinctions between these various capacitors, the applications that each capacitor type tends to be suitable for, and finishes with a discussion of capacitor requirements as related to DC-DC converters.

Tantalum, polymer, ceramic, film, and aluminum capacitors each offer a different set of operating and performance characteristics.

Choosing the proper capacitor when designing DC-DC converters requires a careful understanding of these differences. High voltage front-end connections to the power source typically rely on aluminum capacitors, while intermediate step-down voltages often look towards the tantalum and ceramic families to take advantage of volumetric efficiency.

The final load decoupling and bypass capacitors are generally found in the ceramic and film families.

Types of SMD Capacitors

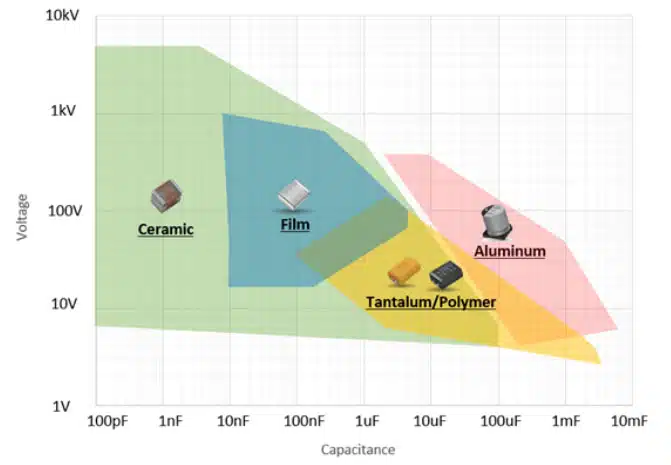

Surface mount (SMD) capacitors can be constructed using several different technologies to achieve a range of voltage tolerance, bulk capacitance, and parasitic device characteristics. As shown in Figure 1, these technologies can be roughly broken down between ceramic, film, tantalum electrolytic, and aluminum electrolytic with varying degrees of application overlap.

It is the job of the circuit designer to select from these capacitor families for a particular application, keeping in mind that multiple capacitors can be combined in series or parallel to achieve their goals. These goals may also include environmental performance, reliability benchmarks, and physical form-factor attributes.

Ceramic Capacitors

Multilayer ceramic capacitors (MLCC) have many advantages in modern electronic design, including small size, high withstand voltage, and long service life. They have become the first choice of engineers for most common bulk capacitance needs, including precision filters, resonators, power supply bypass devices, and decoupling elements. KYOCERA AVX offers a broad range of SMD ceramic capacitors, including the unique Flexiterm and Flexisafe technologies for enhanced safety and reliability.

Film Capacitors

Film capacitors came of age due to advancements in the polymer industry that enabled the metallization of thin plastic dielectrics. These capacitors can be divided into several families based on their application power requirements. On the low end of the spectrum, small surface mount chip capacitors are available in three common dielectrics: metalized Polyethylene Naphtalate (PEN), metalized Polyethylene Terephtalate (PET-HT), and metalized polyphenylene sulfide (PPS). These devices have become ubiquitous on PCBs for various functions, including decoupling, smoothing, filtering, and impedance matching. KYOCERA AVX offers SMD film capacitors with superior features such as high voltage withstanding, low ESR, and no DC bias dependency.

Tantalum Capacitors

Tantalum capacitors are regarded highly in the electrolytic family for their large capacitance per unit volume and generally stable operating parameters. They exhibit self-healing properties and typically provide low electrical series resistance (ESR) with favorable AC impedance characteristics. For these reasons, the two primary applications of tantalum capacitors in circuit design have been as high capacity energy storage elements and as ripple filtering components in power supplies. KYOCERA AVX has been the leading supplier of tantalum capacitors for many years. Their portfolio covers various applications and markets and provides the highest capacitance for limited space (area/height) applications.

Polymer Tantalum Capacitors

Compared to conventional tantalum capacitors based on MnO2 electrolyte, conductive tantalum polymer capacitors have greatly improved conductivity, leading to a significant reduction in ESR through the entire operating frequency range and high ripple current. In addition, the polymer capacitor exhibits a unique self healing mechanism. Dielectric failures result in a high current path that evaporates/carbonizes the polymer material and encapsulates the failure location with a non-conductive polymer layer. The polymer material does not contain any oxygen, unlike MnO2 technology, and is non-flammable. As a result, polymer capacitors are more reliable, safer, and less sensitive to inrush current and higher ripple current limits.

Aluminum Capacitors

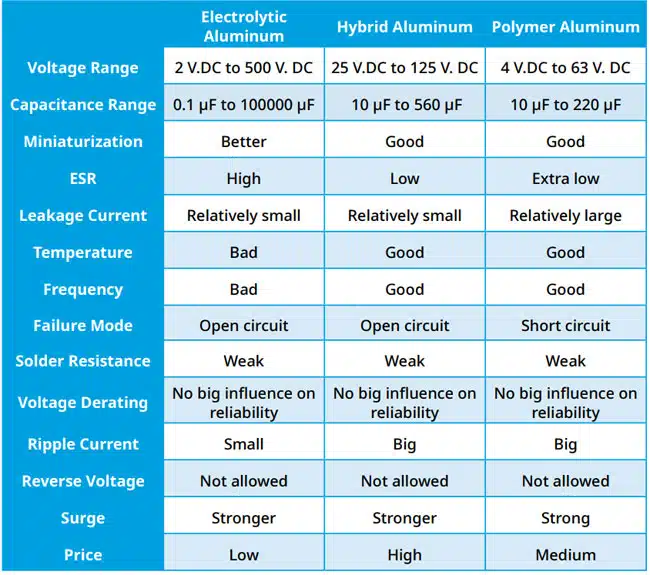

As of 2021, KYOCERA AVX has added aluminum electrolytic capacitors to its product lineup. Table 1 explores the differences between the electrolytic (AEA/AEH series), hybrid (AHA/AHC series), and polymer (APA/APD series). It summarizes the strengths and weaknesses of aluminum, polymer aluminum, and hybrid aluminum electrolytic capacitors. In general, traditional aluminum electrolytic devices offer the lowest cost, smallest form factor option. When other parameters are critical to a design, tradeoffs can be made with hybrid and polymer devices to achieve a longer lifetime, reduced parasitics, and environmental tolerance, to name a few examples.

Capacitor Requirements for DC-DC Converters

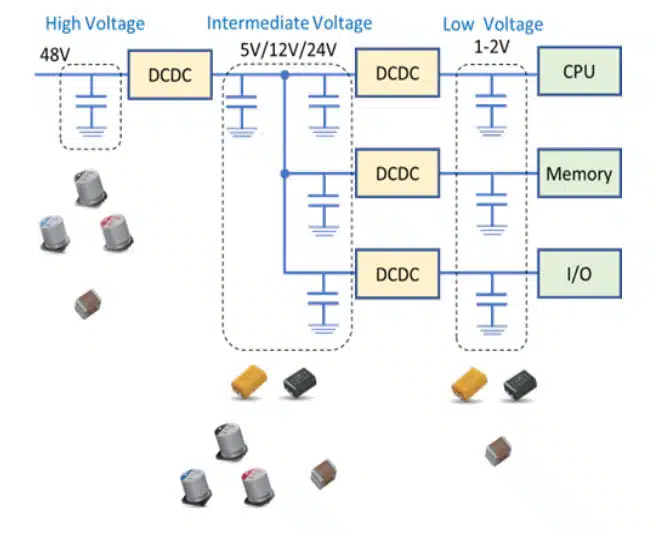

DC-DC converters are often integrated into systems with numerous voltage domains. In the example (Figure 2), the high voltage source is first converted to an intermediate voltage to reduce the input range requirements of the downstream converters. This step will often use a buck converter to maximize efficiency and reduce thermal stress. The resulting intermediate voltage is then converted using a combination of buck, boost, and linear regulators to the specific voltages required for each subsystem.

In the high voltage domain (i.e., 48V), aluminum capacitors are the first choice in most cases. Bulk capacitance and input voltage tolerance are the two most important parameters. In applications with a height restriction, parallel MLCC devices may also be used. In the intermediate voltage domain (i.e., 5V/12V/24V), aluminum capacitors may still be the best option if there is no height restriction. However, more commonly, tantalum/polymer and MLCC are selected to achieve the smallest PCB volume.

In the low voltage domain (i.e., 1-2V), ceramic and film capacitors are the most suitable solution, especially when the switching frequency is higher than a few megahertz. If high bulk capacitance is required, tantalum/polymer can be used to minimize component count and reduce PCB volume.

Conclusion

Figure 3 summarizes the key capacitor technologies suitable for DC-DC converter applications. Depending on the individual application requirements, appropriate devices can be chosen based on bulk capacitance, voltage range, form factor, and price, to name a few parameters.