Exxelia to showcase Smart Integrated Magnetics and advanced MML film capacitors at SIAE 2025.

Exxelia, a designer and manufacturer of high-reliability passive electronic components, announces its participation in the 55th edition of the International Paris Air Show (SIAE 2025).

The show will take place in Le Bourget, France, from Monday, June 16 to Sunday, June 22, 2025. Exxelia will exhibit at Booth 2B – E106, where the company will present its latest innovations designed for weight and volume saving for power electronics in the aerospace & defense sectors.

Exxelia’s focus at SIAE 2025 will be on its innovations in Smart Integrated Magnetics and MML Film Capacitors.

Smart Integrated Magnetics: Optimizing power conversion

supporting innovative architectures: Phase Shift (Dual Active Bridge, ..), LLC, Interleaved converter

Exxelia’s Smart Integrated Magnetics combine multiple functions (Inductor + Transformer) into a single compact component, contributing to systems miniaturization and mass reduction. These components are designed to minimize losses, achieving efficiencies above 99% even at high operating frequencies (10 kHz to 500 kHz).

Their compatibility with advanced silicon carbide (SiC) and gallium nitride (GaN) semiconductors enables the design of more compact and lighter power converters. The technology offers a wide range of inductance values with a high accuracy. The integrated design contributes to a reduction in total cost of ownership.

These components are suitable for demanding applications such as electric or hybrid mobility (aerospace including eVTOLs), military/defense systems, electrical energy storage systems and smart grids, supporting power levels up to 300 kW.

Smart Integrated Magnetics – Representative technical specifications

Reference design of Dual Active Bridge (DAB)

| Rated power | Operating frequency | Inductance | Dimensions | Mass | Key features |

| 25 kW | 100 kHz | 28 µH | 120*110*60mm | 2 kg | High Power density 32 W/cm3 |

| 5 KW | 100 kHz | 18 µH | 75*75*45mm | 750g | High Efficiency 99.5% |

| 2 kW | 300 kHz | 10 µH | 45x40x46 mm | 250g | Compact design, high frequency |

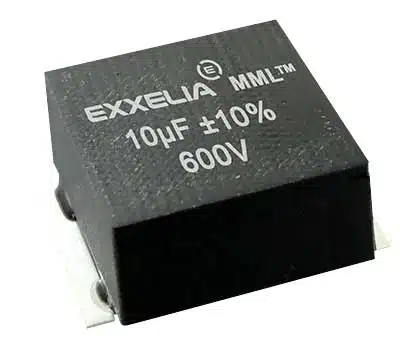

MML Film capacitors: High-density, high-reliability solutionns

Qualified according to MIL-STD 202 and a qualified ESA assessment, MML film capacitors are designed for high-reliability environments. They feature an open-circuit failure mode with self-healing properties, ensuring long-term operational integrity. They maintain stable performance over a wide operating temperature range, from -55°C to +140°C. The capacitance range varies from 100nF ~ 5000µF and voltage up to 2000V DC. Exxelia also offers highly customizable MML solutions, including various case types (D, M, C series) and custom designs to optimize integration, Thermal heating monitoring with Thermo couples, and specific electrical characteristics for unique application requirements.

MML capacitors are used in critical applications such as power converters, energy management systems, payloads, telemetry, flight controls, charge/discharge circuits, generators, and electric motors. They are tested to meet various environmental and durability standards, including humidity (MIL-STD-202 Method 103), barometric pressure (Method 105), thermal shock (Method 107), and life test (Method 108).

MML Film capacitors – Key performance advantages

| Characteristic | MML Performance | Comparative advantage |

| Energy density | Up to 4x higher | Compared to other film dielectrics |

| Mass reduction | Up to 90% lighter | Compared to MLCCs |

| Size reduction | Up to 4x smaller | Compared to traditional film technologies |

| Temperature range | -55°C to +140°C | Suitable for harsh thermal environments |

| Reliability | MIL-STD 202, qualified ESA assessment | High reliability for critical applications |

| Self-healing | Yes | Prevents catastrophic failures, ensures integrity |

Exxelia’s commitment to innovation and sustainability

Exxelia’s continuous investment in research and development underscores its commitment to anticipating and meeting the evolving needs of advanced power electronics. A major strength of Exxelia lies in its non-obsolescence policy, ensuring the long-term availability of its components and thus contributing to an eco-responsible approach by extending the lifespan of electronic systems. This commitment is reinforced by an environmental policy aimed at reducing hazardous substances and prioritizing waste recycling.